Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

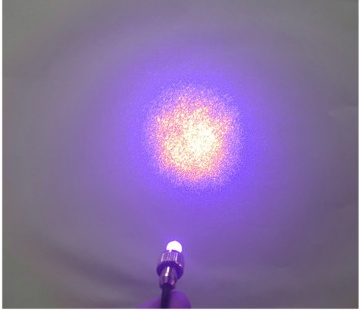

From healthcare gadgets to tiny electronics, laser tech has reshaped countless fields. Among the many kinds of lasers we have today, violet lasers—which give off light around 405 nanometers—are special because of their unique color and precision. That eye-catching purple-blue glow isn't just for looks; it's key for storing huge amounts of data, advanced imaging, and working with delicate materials. In fact, the same violet laser tech that brought us Blu-ray discs is now making waves in medicine, research, and factory floors.

Why are violet lasers getting so much attention? It comes down to their sharp focus and energy profile. They hit a sweet spot—combining the deep penetration of blue lasers with the fine detail of ultraviolet light. That makes them perfect for jobs where you need both accuracy and control.

Basically, violet lasers are used wherever you need high precision and concentrated energy—from optical storage and biophotonics to fluorescence microscopy, checking semiconductor chips, and laser engraving. Their wavelength sits right between visible and ultraviolet light, letting them do things other lasers can't do as well.

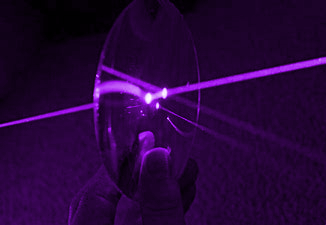

To get why violet lasers are so useful, it helps to know a little about how they operate. Violet lasers emit light at about 405 nm—on the light spectrum, that’s between blue and ultraviolet. Because their wavelength is shorter than red or green lasers, they can focus more tightly and show finer details.

The heart of these lasers is a semiconductor diode made from gallium nitride (GaN). GaN diodes efficiently produce violet light, offering strong and steady beams even in small devices. That ability to stay compact has made violet lasers a go-to for everything from consumer gadgets to lab tools.

What’s more, shorter wavelengths mean violet lasers can zero in on tinier spots. That makes them great for etching, cutting, or scanning with extra precision—something crucial in areas like micro-manufacturing, data storage, and biological imaging. Compared to infrared or red lasers, violet lasers deliver cleaner details and can pack information more densely.

One of the earliest—and most well-known—uses of violet lasers was in optical storage, especially Blu-ray discs. The 405 nm wavelength let them write data in much smaller “pits” on a disc compared to DVDs or CDs, which relied on red lasers. That meant a lot more data could fit in the same space.

For example, a Blu-ray disc can hold about five times more than a standard DVD, thanks largely to the violet laser’s shorter wavelength. The improved precision also meant fewer read/write errors, making the tech both more efficient and reliable.

Even though physical discs aren't as common now with cloud storage on the rise, the violet laser diodes developed for Blu-ray are still hard at work—especially in fields that need an affordable, compact laser for precision tasks.

In medicine and science, violet lasers have become essential. Their short wavelength is perfect for lighting up fluorescent dyes and proteins used in biological imaging. In flow cytometry or fluorescence microscopy, for instance, violet lasers help tell different cell types apart based on how they glow.

Beyond imaging, these lasers are used in dermatology and dentistry. Their wavelength works well for killing bacteria and interacting with tissue without causing much heat damage. Dentists use violet diode lasers for gentle cleaning and prepping surfaces, while skin doctors apply them in non-invasive treatments for acne or pigmentation issues.

Violet lasers also play a role in DNA sequencing and diagnostic testing. Their ability to activate fluorescent tags with high accuracy helps researchers spot genetic markers and specific molecules reliably.

Violet lasers are increasingly found in precision manufacturing. Thanks to their short wavelength, they focus very tightly—ideal for micro-engraving, inspecting semiconductors, and cutting thin films. These jobs require extreme accuracy, where even a tiny mistake can cause problems.

For instance, in electronics manufacturing, violet lasers can mark or drill extremely fine patterns onto circuit boards or silicon wafers. They produce only a small heat-affected zone, which helps avoid warping sensitive parts.

They're also used in laser lithography, a technique that uses light to draw tiny patterns onto silicon wafers. Because violet light focuses tighter than red or green, it can create smaller and more detailed structures—pushing forward the trend of making electronics ever smaller.

Researchers are also putting violet lasers to work in new ways. Their high photon energy makes them great for studying quantum effects, optical trapping, and spectroscopy. In spectroscopy, violet lasers help analyze how materials absorb or scatter light, letting scientists examine substances at the molecular level.

In security and forensics, violet lasers help authenticate documents and uncover hidden fingerprints. Certain inks and dyes light up under violet light, revealing details you can’t see normally. That’s useful for checking official papers, spotting fakes, and helping solve crimes.

You'll also find violet lasers in modern projection systems and laser shows. Their vivid color and sharp focus help create bright, high-resolution displays when combined with red and green lasers.

Violet lasers fill a special niche in today's tech world. Their short wavelength, high resolution, and flexibility help them bridge the gap between everyday visible light and ultraviolet applications. From reading Blu-rays to analyzing DNA and engraving microchips, they keep shaping how industries work.

As research moves forward, violet laser diodes are expected to become even more powerful, efficient, and affordable. We may soon see them in new kinds of displays, quantum computers, and nanotech.

All in all, violet lasers aren't just precise tools—they're driving progress across science, medicine, and manufacturing. Their ability to deliver concentrated, high-energy light will keep them at the heart of innovation for a long time to come.

Violet lasers usually give off light around 405 nanometers—between blue and ultraviolet on the spectrum.

Like all lasers, they can be harmful if used improperly. Always wear the right protective glasses and follow safety guidelines.

Violet lasers have a shorter wavelength (around 405 nm) compared to blue lasers (around 445–460 nm), which makes them better for fine, detailed work.

Yes, though they're best for micro-engraving or fine marks on coated or delicate surfaces rather than deep cuts in thick metal.

The shorter wavelength allowed Blu-ray discs to store a lot more data than DVDs or CDs by writing smaller, tighter data pits.