Views: 0 Author: Site Editor Publish Time: 2025-11-14 Origin: Site

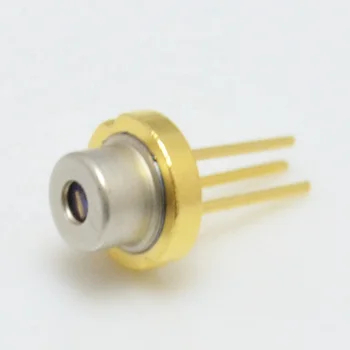

Diode lasers are small, energy-efficient, and affordable. These traits make them indispensable in various industries. From consumer electronics to medical devices, their versatility is unmatched.

In this article, we'll explore the key applications and benefits of diode lasers across multiple sectors. You'll discover how they are shaping modern technology and everyday solutions.

Diode lasers are widely used across multiple industries due to their compact design, energy efficiency, and affordability. Below, we'll explore the core applications where diode lasers truly shine.

Diode lasers play a crucial role in modern consumer electronics. Their small size and efficiency make them ideal for devices we use every day.

Diode lasers are essential in fiber-optic networks, where they act as light sources for data transmission. Their ability to emit light at precise wavelengths ensures fast and reliable communication over long distances. This makes them indispensable in internet and telecom systems, enabling quick, high-bandwidth data transfer.

You might not realize it, but diode lasers power many features in everyday gadgets. Smartphones use them for facial recognition, where the laser projects patterns onto the face for secure access. Diode lasers are also found in optical drives (such as CD/DVD players) and laser pointers, offering low-power, high-precision performance.

In the world of display technology, diode lasers are used in laser projectors and TV backlighting. They help provide bright, clear images with excellent color reproduction. These projectors are more energy-efficient than traditional methods, making them a preferred choice for both home and professional use.

Diode lasers have gained popularity in hobbyist and small-business applications, offering affordable solutions for those who need precision without the heavy investment.

Small businesses often rely on diode lasers for engraving and marking tasks. These lasers can work on materials like plastic, leather, and wood, making them perfect for custom products like keychains or branded merchandise. The precision and cost-effectiveness of diode lasers make them a go-to tool for small-scale engraving.

For hobbyists, diode lasers offer a low-cost solution for engraving and creating custom items. They are commonly used in DIY setups to make personalized designs on various materials. Whether you're creating models, art pieces, or custom gifts, diode lasers provide the power needed without the cost of industrial-grade machines.

Compared to high-power industrial lasers, diode lasers are an affordable entry point for small businesses. Their ease of integration into home workshops or small production facilities allows businesses to start with minimal investment. This makes them particularly appealing for entrepreneurs who want to offer custom solutions without the need for large-scale equipment.

The versatility of diode lasers extends to the medical field, where their low power and precision are highly valued.

Diode lasers are commonly used in low-intensity therapies. They can treat skin conditions like acne, promote hair removal, and even aid in pain reduction. Their gentle energy makes them suitable for therapies that require consistent, precise application without causing harm to the skin or underlying tissues.

In medical treatments, diode lasers are frequently employed in minimally invasive surgeries. For example, they are used in eye treatments (like LASIK) and dental procedures. Their precision allows for delicate procedures, reducing the need for more invasive methods, and promoting faster recovery times for patients.

Diode lasers also find use in medical diagnostics and imaging. Their compact size makes them ideal for portable medical equipment, such as diagnostic imaging tools and biosensors. With their stable light output, diode lasers help doctors conduct accurate tests and provide timely diagnoses.

While diode lasers may not have the power of larger lasers, they excel in specific industrial tasks that require finesse over brute force.

One of the key industrial applications of diode lasers is in laser pumping. They serve as energy sources for fiber lasers and solid-state lasers, boosting their power output. This application is essential in high-power laser systems, where diode lasers help initiate the laser process by providing energy to the gain medium.

Diode lasers are also used for light-duty processing tasks such as cutting, welding, and soldering. They are ideal for working with delicate materials like thin plastics and microchips, which require precision rather than raw power. This makes diode lasers a valuable tool in electronics manufacturing and other industries where fine-tuned work is needed.

Due to their stable wavelength output, diode lasers are commonly used in LIDAR systems, environmental sensors, and industrial detectors. These systems rely on diode lasers to measure distances or detect environmental changes. Their precision and reliability make them a perfect fit for applications that require real-time monitoring and data collection.

Application | Key Uses |

Optical Communication | Light source for fiber-optic networks, enabling fast data transmission. |

Device Features | Powering facial recognition, optical drives, and laser pointers. |

Display Technology | Used in laser projectors and TV backlighting for energy-efficient displays. |

Engraving & Marking | Engraving plastic, leather, wood, ideal for small businesses and DIY. |

DIY & Custom Projects | Low-cost solution for hobbyists creating custom designs. |

Low-Intensity Therapy | Treating skin conditions, hair removal, and pain reduction. |

Minimally Invasive Surgery | Used in procedures like LASIK and dental treatments. |

Laser Pumping | Provides energy for fiber and solid-state lasers in industrial applications. |

Light-Duty Processing | Cutting, welding, and soldering delicate materials like plastics. |

Sensing & Monitoring | Used in LIDAR systems and industrial sensors for accurate measurements. |

Diode lasers are popular in many industries, but how do they stack up against other laser types like fiber and CO₂ lasers? Let’s break down their core differences in terms of strengths, material compatibility, industrial applications, and costs.

Diode lasers are known for their compact size, affordability, and energy efficiency. They are smaller and lighter than fiber and CO₂ lasers, making them easier to integrate into portable applications or consumer devices. Their low power consumption means they can be used in a wide range of environments without worrying about excessive heat generation.

In comparison, fiber lasers are known for their high precision and power. They are great for heavy-duty industrial tasks where high intensity is required, such as metal cutting and welding. CO₂ lasers, on the other hand, are more suited for cutting non-metal materials like wood and glass, offering a longer wavelength and greater efficiency with those materials.

Diode lasers are ideal for working with plastics, leather, and thin wood. Their precision and low-power output make them perfect for engraving, marking, and cutting these materials. While they can also work on some metals, the depth and precision of the cuts are typically more limited compared to fiber lasers.

Fiber lasers, due to their high power, are better suited for metals such as stainless steel, aluminum, and copper. They can create precise, deep cuts and welds. CO₂ lasers, with their longer wavelength, excel at cutting materials like wood, glass, and ceramics, where the energy absorption properties of those materials are ideal for CO₂ laser cutting.

Diode lasers are excellent for light-duty tasks in various industries. They can be used for engraving and cutting thin plastics, wood, and leather, making them a great option for small businesses and hobbyists. Their ability to be integrated into affordable, compact machines makes them accessible to many who might not have the budget for high-power systems.

On the other hand, fiber lasers dominate in high-precision industrial applications like metal cutting and welding. They are often used in manufacturing processes where speed and precision are crucial. CO₂ lasers are widely used in large-scale non-metal cutting applications such as sign making, packaging, and textile cutting.

One of the main advantages of diode lasers is their low upfront cost. They are much more affordable than fiber and CO₂ lasers, making them accessible to small businesses and individual users. In contrast, fiber lasers have a much higher initial cost due to their advanced technology and high precision. CO₂ lasers, while more affordable than fiber lasers, still tend to be more expensive than diode lasers, especially for high-power models.

Maintaining a diode laser involves keeping it clean and ensuring it is stored in a stable environment. Dust, humidity, and extreme temperatures can damage the delicate internal components. Regular cleaning and proper storage help extend the lifespan and maintain performance.

Fiber and CO₂ lasers also require careful maintenance, especially in industrial environments. However, the environmental requirements are often stricter for these lasers, as they generate more heat and may require cooling systems to prevent overheating.

The quality of the driver is crucial for the performance of a diode laser. A well-designed driver ensures proper power flow and helps avoid voltage spikes that could damage the laser. Poor-quality drivers, on the other hand, can shorten the laser’s lifespan and compromise its performance.

Fiber and CO₂ lasers also rely on quality drivers, but because they are generally used for higher power applications, they tend to have more robust and complex systems in place.

Laser Type | Strengths | Best Materials | Applications | Cost |

Diode Lasers | Compact, affordable, energy-efficient | Plastics, leather, thin wood | Small-scale engraving, marking, light cutting | Low upfront cost |

Fiber Lasers | High power, high precision | Metals (stainless steel, aluminum) | Heavy-duty industrial cutting, welding, engraving | High upfront cost |

CO₂ Lasers | Ideal for non-metal cutting, long wavelength | Wood, glass, ceramics | Large-scale cutting, packaging, signage | Medium-high upfront cost |

As technology advances, so do the capabilities of diode lasers. These lasers have already found their place in many industries, from consumer electronics to medical devices. But the future of diode lasers is even more exciting. Let’s take a closer look at how diode lasers are evolving and the challenges that remain.

Recent advancements in diode laser technology have focused on enhancing their performance. The latest developments aim to increase their power output while maintaining the compact size that makes them so popular. These advancements often involve improving the materials used for the diode itself and optimizing the design of the laser drivers.

For example, new semiconductor materials are being explored that could boost the efficiency and power of diode lasers, making them even more effective in industrial and medical applications. This could lead to lasers that perform as well as fiber or CO₂ lasers but at a much lower cost.

Diode lasers are already used in many fields, but their potential is far from fully realized. As their efficiency improves, diode lasers are expected to play a major role in new fields such as advanced manufacturing, space exploration, and automated systems. They could be used in precision tasks like 3D printing of high-performance materials or even in laser cutting for more complex applications.

Tip: In the medical field, diode lasers could revolutionize non-invasive surgeries or therapeutic treatments with better precision and lower energy consumption. They could also be used for diagnostics in portable medical devices, making them more affordable and accessible.

Despite their many advantages, diode lasers still face material limitations. While they excel at working with materials like plastics, wood, and leather, they struggle with harder materials like metals, which require more intense energy for deep cutting or engraving.

To overcome these limitations, research is ongoing into new diode materials that could handle tougher substances. Blue and violet diodes, for example, can work better with metals compared to traditional red diodes, but further development is still needed to fully expand their capabilities.

Another challenge for diode lasers is their durability. While they are generally more affordable than fiber and CO₂ lasers, diode lasers have a shorter lifespan compared to their counterparts. This is mainly due to their sensitive components, which can degrade over time, especially in industrial settings where they are subject to heavy use.

To improve longevity, researchers are working on better cooling systems and more durable materials for diode laser construction. Keeping these lasers in a stable environment—free from dust, extreme temperatures, and humidity—is also crucial for extending their lifespan.

Aspect | Diode Lasers | Fiber Lasers | CO₂ Lasers |

Efficiency | Improving with new materials | High efficiency for industrial use | Moderate efficiency for non-metals |

Cost | Low upfront cost | High upfront cost | Medium-high upfront cost |

Material Compatibility | Best for plastics, wood, leather | Ideal for metals (stainless steel, aluminum) | Best for non-metals (wood, glass) |

Durability | Shorter lifespan, maintenance needed | Longer lifespan, industrial-grade | Moderate lifespan, sensitive to heat |

Diode lasers offer great versatility, excelling in consumer technology, hobbyist projects, medical devices, and low-power industrial tasks. Their affordability, compact size, and energy efficiency make them an ideal choice for many applications.

Choosing the right laser is essential, and diode lasers fill a critical gap in fields where high-power lasers are unnecessary. At BU-LASER, we offer high-quality diode lasers that deliver reliable performance and value for various applications. Our products are designed to meet the needs of industries seeking efficient, cost-effective solutions.

A: A diode laser is commonly used in consumer electronics, medical devices, and small-scale industrial applications. It is ideal for tasks like engraving, marking, and cutting plastics, leather, and wood.

A: Diode lasers are affordable, compact, and energy-efficient. They work well for low-power tasks where higher-power lasers like fiber or CO₂ lasers are unnecessary.

A: While diode lasers are ideal for lighter tasks, fiber lasers excel in high-precision, high-power applications, particularly in metal cutting and welding.

A: Yes, diode lasers are generally more affordable than fiber and CO₂ lasers, making them a great choice for small businesses and DIY projects.