| Availability: | |

|---|---|

| Quantity: | |

GH04C06W9G

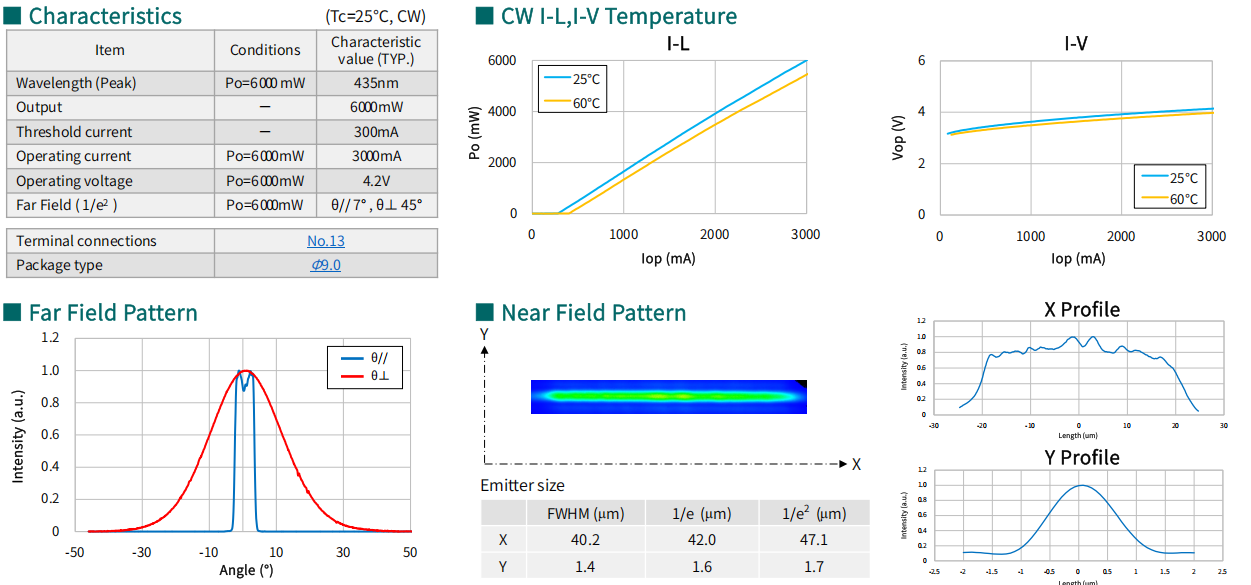

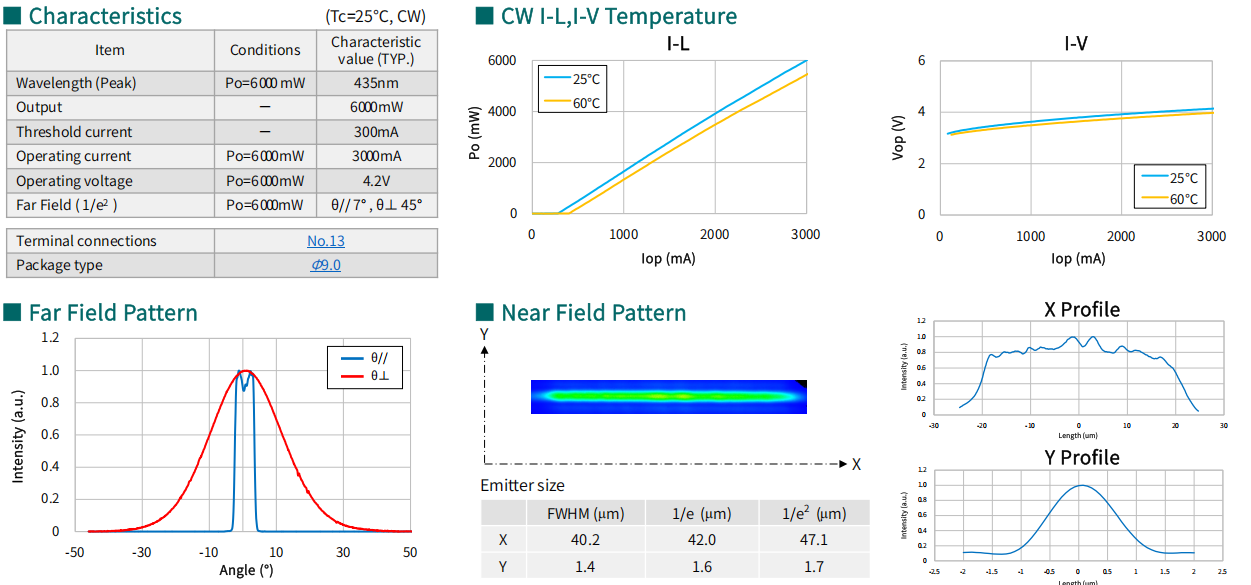

The High Power TO5 9mm 435nm 6W Blue Laser Diode GH04C06W9G—a cutting-edge single-emitter light source optimized for high-intensity industrial applications. Leveraging Sharp's advanced multi-mode laser diode technology, this 435nm blue wavelength device delivers 6W CW peak power in a compact TO5 9mm CAN package, combining exceptional brightness, superior material absorption, and reliable performance for demanding industrial, scientific, and specialty applications.

Ultra-High Power 435nm Wavelength: Exceptional Material Interaction

435nm (±5nm) blue-violet wavelength offers 4–10x higher absorption on copper, gold, aluminum, and other non-ferrous metals compared to 1064nm IR lasers.

6W CW output power (at Tc=25°C) enables rapid material processing with minimal thermal damage.

Multi-mode TE oscillation ensures uniform energy distribution for consistent results across large areas.

Compact TO5 9mm CAN Package: Space-Efficient Integration

Aperture size: 45μm emitter width for precise beam control

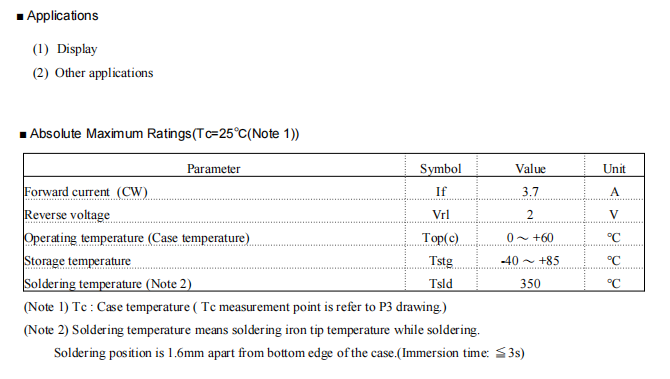

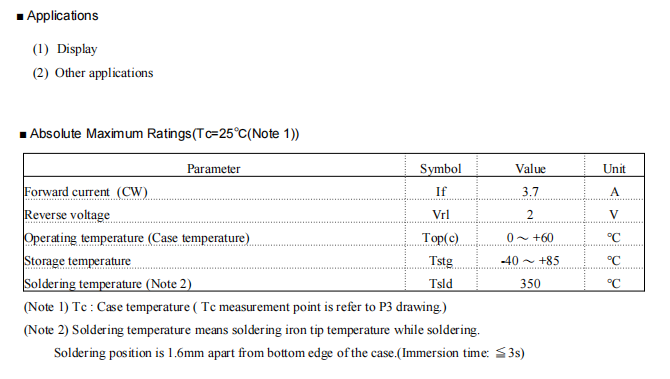

1. Industrial Material Processing

Laser vaporization and thin-film deposition for semiconductor manufacturing.

High-speed marking and engraving on metals, plastics, and ceramics.

Precision cutting of thin materials (≤1mm) with minimal heat-affected zone.

Soldering and welding of copper and gold components (4–10x faster than IR lasers).

2. Scientific Research & Instrumentation

Material science experiments (vaporization kinetics, surface modification).

Fluorescence excitation source for biological and chemical analysis.

High-power light source for spectroscopy and interferometry.

Prototype development for next-generation laser systems.

3. Specialty Manufacturing

Medical device processing (sterile marking, precision cutting).

3D printing of metal and polymer materials.

Electronic component repair and rework.

Display technology (backlighting, projection systems).

4. Automation & Robotics

Integrated laser systems for automated production lines.

Machine vision and alignment systems require high-intensity blue light.

Quality control inspection with high contrast illumination.

The High Power TO5 9mm 435nm 6W Blue Laser Diode GH04C06W9G—a cutting-edge single-emitter light source optimized for high-intensity industrial applications. Leveraging Sharp's advanced multi-mode laser diode technology, this 435nm blue wavelength device delivers 6W CW peak power in a compact TO5 9mm CAN package, combining exceptional brightness, superior material absorption, and reliable performance for demanding industrial, scientific, and specialty applications.

Ultra-High Power 435nm Wavelength: Exceptional Material Interaction

435nm (±5nm) blue-violet wavelength offers 4–10x higher absorption on copper, gold, aluminum, and other non-ferrous metals compared to 1064nm IR lasers.

6W CW output power (at Tc=25°C) enables rapid material processing with minimal thermal damage.

Multi-mode TE oscillation ensures uniform energy distribution for consistent results across large areas.

Compact TO5 9mm CAN Package: Space-Efficient Integration

Aperture size: 45μm emitter width for precise beam control

1. Industrial Material Processing

Laser vaporization and thin-film deposition for semiconductor manufacturing.

High-speed marking and engraving on metals, plastics, and ceramics.

Precision cutting of thin materials (≤1mm) with minimal heat-affected zone.

Soldering and welding of copper and gold components (4–10x faster than IR lasers).

2. Scientific Research & Instrumentation

Material science experiments (vaporization kinetics, surface modification).

Fluorescence excitation source for biological and chemical analysis.

High-power light source for spectroscopy and interferometry.

Prototype development for next-generation laser systems.

3. Specialty Manufacturing

Medical device processing (sterile marking, precision cutting).

3D printing of metal and polymer materials.

Electronic component repair and rework.

Display technology (backlighting, projection systems).

4. Automation & Robotics

Integrated laser systems for automated production lines.

Machine vision and alignment systems require high-intensity blue light.

Quality control inspection with high contrast illumination.