| Availability: | |

|---|---|

| Quantity: | |

LY450-20W-SF200

The 200μm 450nm 20W Blue Fiber Coupled Laser Module—a heavy-duty industrial-grade high-power blue light source engineered for high-throughput precision manufacturing, including large-format laser microfabrication, thick-layer UV-curing, high-speed SLA 3D printing, and metal/nonmetal surface modification. Optimized for 450nm blue light’s superior nonmetallic material absorption characteristics, this module features 20W stable CW output, 200μm UV-grade fiber’s balanced energy density and uniform transmission, and an upgraded industrial-grade thermal management system. It delivers ultra-high processing efficiency, 24/7 continuous operation capability, and flexible integration, perfectly matching the technical demands of automated industrial production lines and heavy-load precision processing equipment—an ideal core light source for medium-to-large batch manufacturing in electronics, aerospace, and new material processing industries.

450nm (±5nm tolerance) high-purity blue light is the gold standard for industrial nonmetallic processing: achieves 3–5x higher absorption efficiency on acrylate photoresists, UV-curable composites, wood, acrylic, and engineering plastics than infrared lasers, minimizing heat-affected zones (HAZ ≤1μm) and avoiding material charring/warpage in precision processing.

Excellent photochemical reaction activity and metal surface modification capability: 450nm blue light induces effective surface activation of copper, aluminum, and stainless steel, improving the adhesion of coatings/adhesives by over 60%—ideal for semiconductor packaging and electronic component bonding.

Narrow spectral linewidth (≤5nm FWHM) eliminates chromatic aberration of industrial processing equipment’s optical systems, ensuring uniform energy distribution at the fiber tip. No stray light output avoids interference with automated production line detection systems, ensuring consistent processing quality for batch products.

20W industrial-grade stable CW output (0–20W stepless adjustable) breaks through the power bottleneck of low-power blue laser modules, cutting processing cycle time by 80% compared to 5W/10W alternatives. It supports one-pass processing of 10mm-thick acrylic/15mm-thick basswood and high-speed curing of 8mm-thick UV-curable adhesives, perfectly adapting to high-throughput automated production lines.

| Application Scenario | Core Benefits & Processing Capability |

|---|---|

| Thick-Layer UV-Curing for Electronics | One-pass curing of 8–12mm thick UV-curable adhesives/conformal coatings; 200μm fiber’s uniform energy distribution eliminates edge under-curing—ideal for automotive electronic component bonding, semiconductor packaging, and FPC rigid-flex board lamination. |

| Large-Format High-Speed SLA 3D Printing | 20W high power cuts print time by 75% compared to 10W modules; supports 800mm×800mm large build platforms and 25μm ultra-fine layer thickness; suitable for mass production of industrial structural parts, aerospace prototypes, and mold inserts. |

| Nonmetal Precision Cutting & Engraving | One-pass cutting of 15mm basswood/10mm acrylic with smooth, burr-free edges; high-precision engraving of large-area PCB panels (600mm×600mm) with linewidth ≤2μm—adapts to furniture manufacturing, electronic panel processing, and advertising sign making. |

| Metal Surface Laser Modification | 450nm blue light induces surface activation/oxidation of copper, aluminum, and stainless steel; 20W high power realizes high-speed surface texturing (≥500mm/s) and adhesion enhancement—suitable for automotive parts, hardware accessories, and semiconductor lead frame processing. |

| Laser Microfabrication for New Materials | High-precision structuring of engineering plastic/ceramic micro-components (channel width ≥5μm) with low HAZ; 20W high power improves processing throughput for new energy battery parts and microfluidic chip batch manufacturing. |

| Large-Area Photoresist Exposure | Fast exposure of large-format photoresist-coated substrates (800mm×800mm) for PCB HDI board and display panel manufacturing; uniform energy output ensures consistent pattern transfer across the entire substrate, improving production efficiency. |

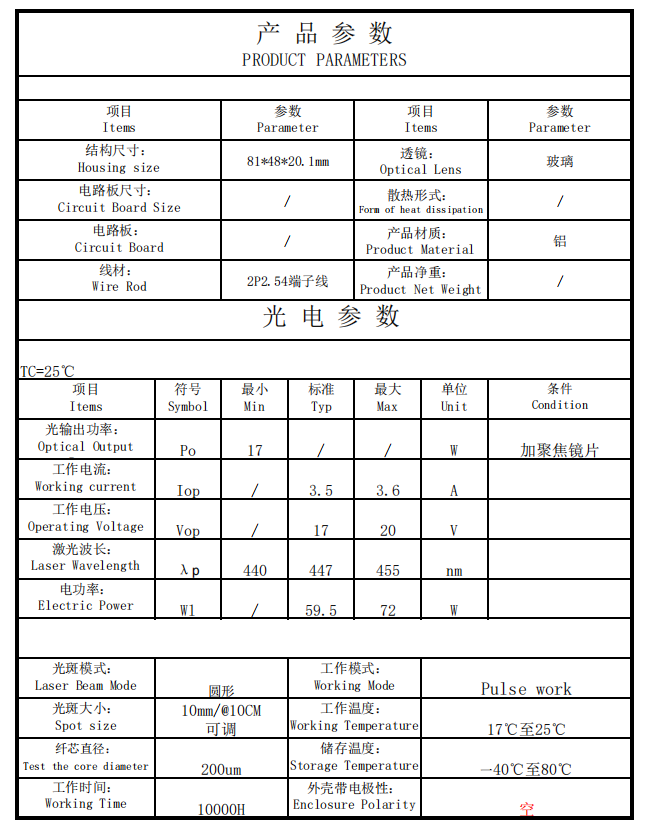

Core Specification :

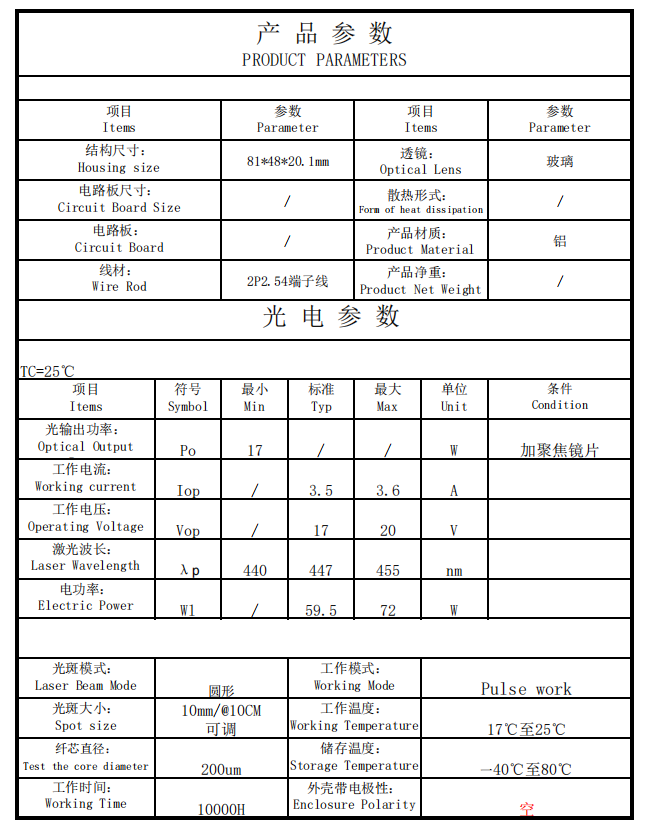

| Wavelength | 455nm |

| Output Power | >17W |

| Working Voltage | 17-20V |

| Fiber Core Diameter | 200um |

| Fiber Interface | SMA 905 (Customizable) |

| Collimated dot Beam size | / |

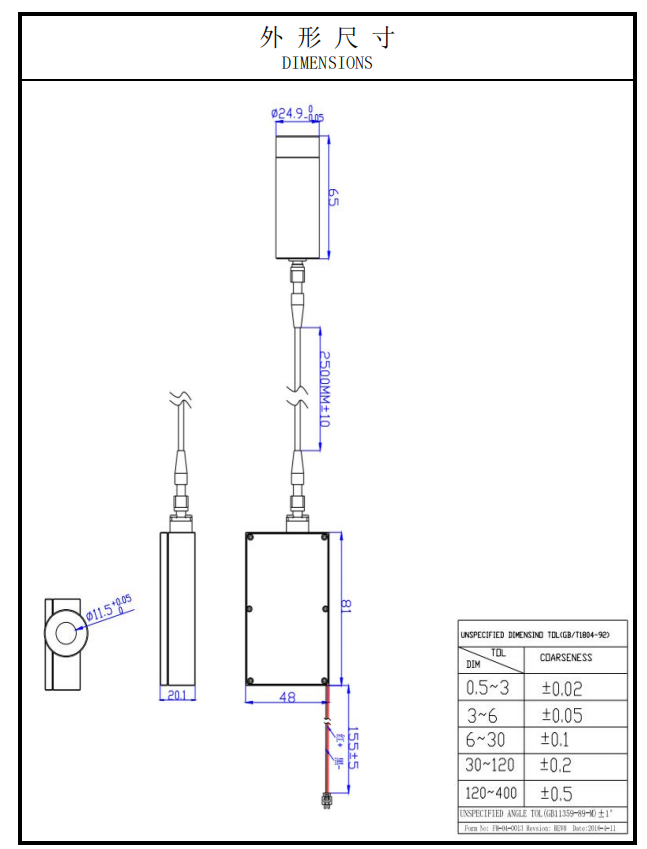

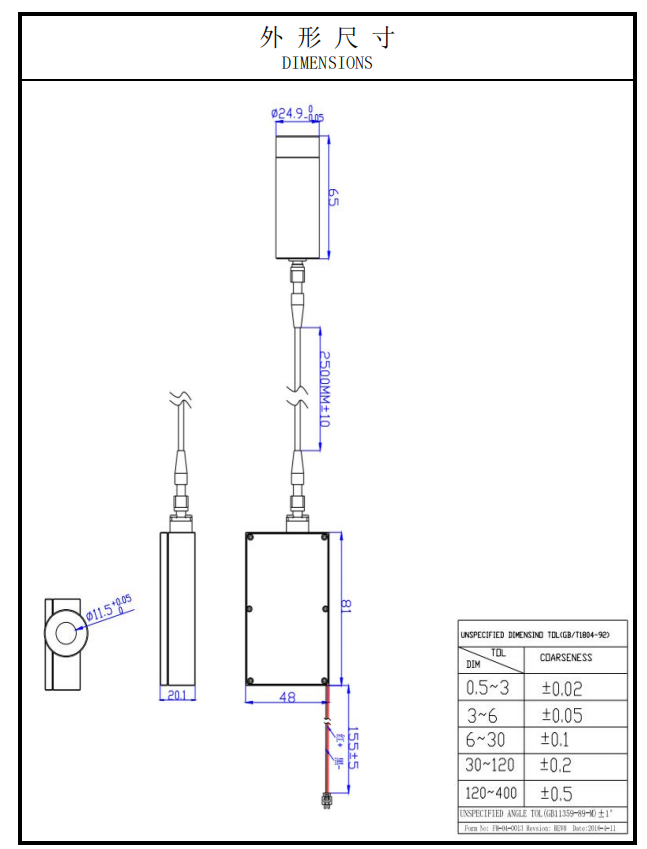

| Housing Size | 81*48*20.1mm (Customizable) |

| Lens | Optical Glass |

| Cooling Method | / |

| Lifespan | > 10,000 hours |

We have over 15 years of experience with Lasers. We offer professional OEM& ODM service for laser modules!

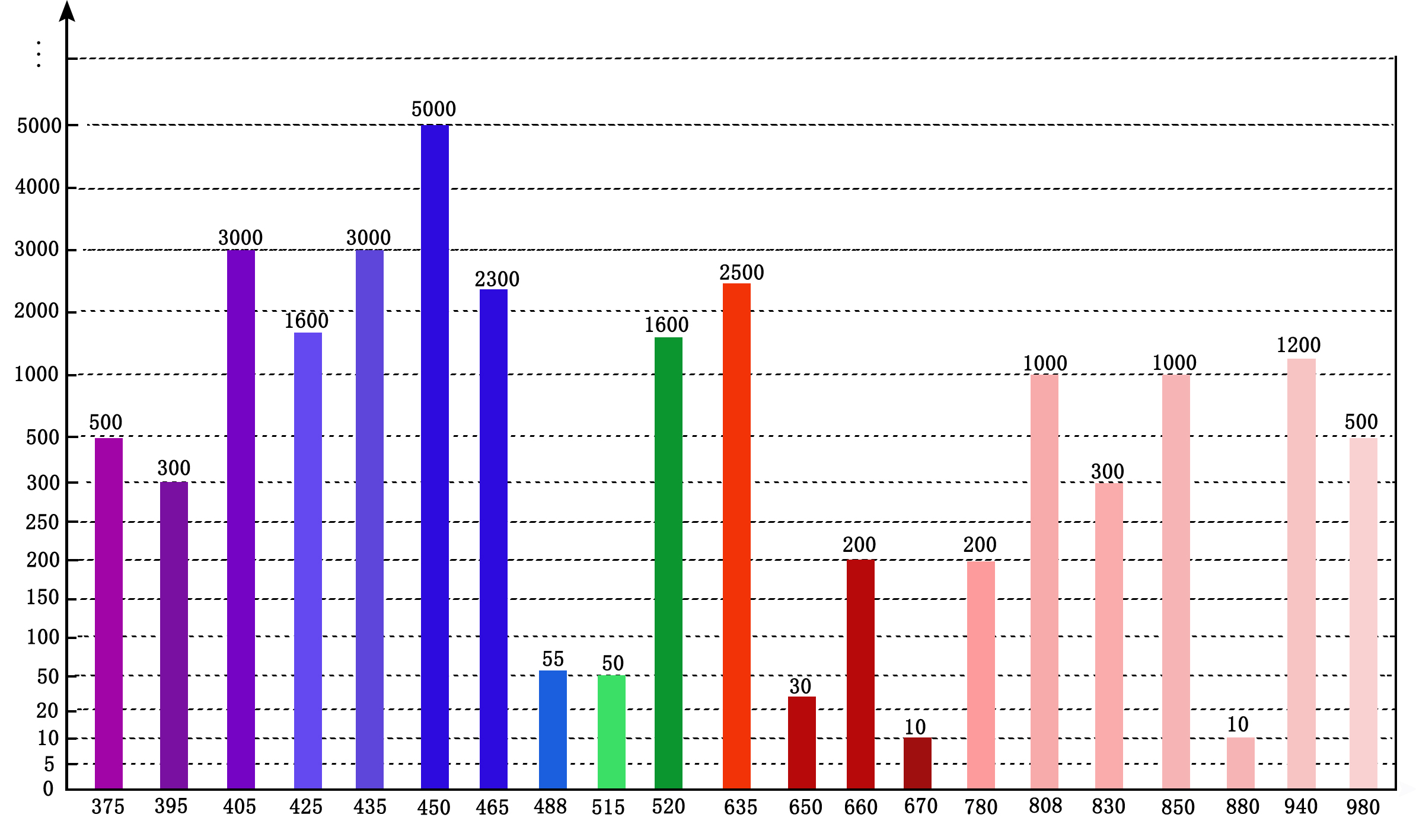

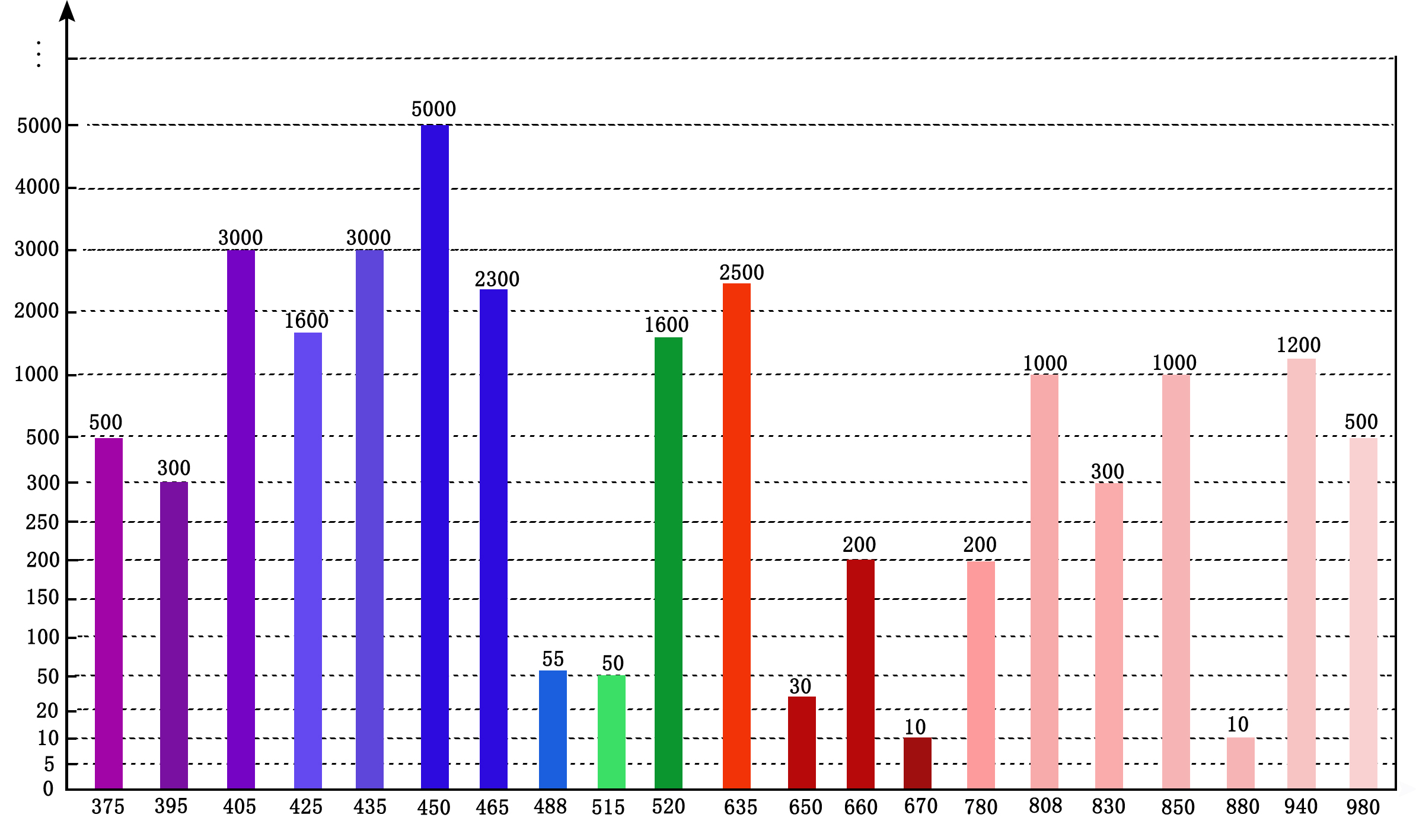

| Item | Parameter | ||||

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/80°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||

The 200μm 450nm 20W Blue Fiber Coupled Laser Module—a heavy-duty industrial-grade high-power blue light source engineered for high-throughput precision manufacturing, including large-format laser microfabrication, thick-layer UV-curing, high-speed SLA 3D printing, and metal/nonmetal surface modification. Optimized for 450nm blue light’s superior nonmetallic material absorption characteristics, this module features 20W stable CW output, 200μm UV-grade fiber’s balanced energy density and uniform transmission, and an upgraded industrial-grade thermal management system. It delivers ultra-high processing efficiency, 24/7 continuous operation capability, and flexible integration, perfectly matching the technical demands of automated industrial production lines and heavy-load precision processing equipment—an ideal core light source for medium-to-large batch manufacturing in electronics, aerospace, and new material processing industries.

450nm (±5nm tolerance) high-purity blue light is the gold standard for industrial nonmetallic processing: achieves 3–5x higher absorption efficiency on acrylate photoresists, UV-curable composites, wood, acrylic, and engineering plastics than infrared lasers, minimizing heat-affected zones (HAZ ≤1μm) and avoiding material charring/warpage in precision processing.

Excellent photochemical reaction activity and metal surface modification capability: 450nm blue light induces effective surface activation of copper, aluminum, and stainless steel, improving the adhesion of coatings/adhesives by over 60%—ideal for semiconductor packaging and electronic component bonding.

Narrow spectral linewidth (≤5nm FWHM) eliminates chromatic aberration of industrial processing equipment’s optical systems, ensuring uniform energy distribution at the fiber tip. No stray light output avoids interference with automated production line detection systems, ensuring consistent processing quality for batch products.

20W industrial-grade stable CW output (0–20W stepless adjustable) breaks through the power bottleneck of low-power blue laser modules, cutting processing cycle time by 80% compared to 5W/10W alternatives. It supports one-pass processing of 10mm-thick acrylic/15mm-thick basswood and high-speed curing of 8mm-thick UV-curable adhesives, perfectly adapting to high-throughput automated production lines.

| Application Scenario | Core Benefits & Processing Capability |

|---|---|

| Thick-Layer UV-Curing for Electronics | One-pass curing of 8–12mm thick UV-curable adhesives/conformal coatings; 200μm fiber’s uniform energy distribution eliminates edge under-curing—ideal for automotive electronic component bonding, semiconductor packaging, and FPC rigid-flex board lamination. |

| Large-Format High-Speed SLA 3D Printing | 20W high power cuts print time by 75% compared to 10W modules; supports 800mm×800mm large build platforms and 25μm ultra-fine layer thickness; suitable for mass production of industrial structural parts, aerospace prototypes, and mold inserts. |

| Nonmetal Precision Cutting & Engraving | One-pass cutting of 15mm basswood/10mm acrylic with smooth, burr-free edges; high-precision engraving of large-area PCB panels (600mm×600mm) with linewidth ≤2μm—adapts to furniture manufacturing, electronic panel processing, and advertising sign making. |

| Metal Surface Laser Modification | 450nm blue light induces surface activation/oxidation of copper, aluminum, and stainless steel; 20W high power realizes high-speed surface texturing (≥500mm/s) and adhesion enhancement—suitable for automotive parts, hardware accessories, and semiconductor lead frame processing. |

| Laser Microfabrication for New Materials | High-precision structuring of engineering plastic/ceramic micro-components (channel width ≥5μm) with low HAZ; 20W high power improves processing throughput for new energy battery parts and microfluidic chip batch manufacturing. |

| Large-Area Photoresist Exposure | Fast exposure of large-format photoresist-coated substrates (800mm×800mm) for PCB HDI board and display panel manufacturing; uniform energy output ensures consistent pattern transfer across the entire substrate, improving production efficiency. |

Core Specification :

| Wavelength | 455nm |

| Output Power | >17W |

| Working Voltage | 17-20V |

| Fiber Core Diameter | 200um |

| Fiber Interface | SMA 905 (Customizable) |

| Collimated dot Beam size | / |

| Housing Size | 81*48*20.1mm (Customizable) |

| Lens | Optical Glass |

| Cooling Method | / |

| Lifespan | > 10,000 hours |

We have over 15 years of experience with Lasers. We offer professional OEM& ODM service for laser modules!

| Item | Parameter | ||||

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/80°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||