| Availability: | |

|---|---|

| Quantity: | |

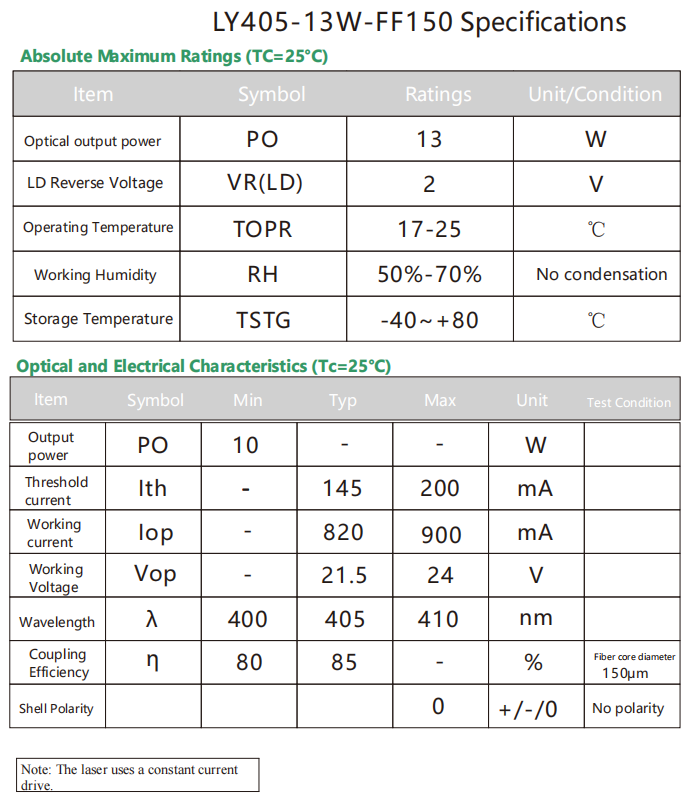

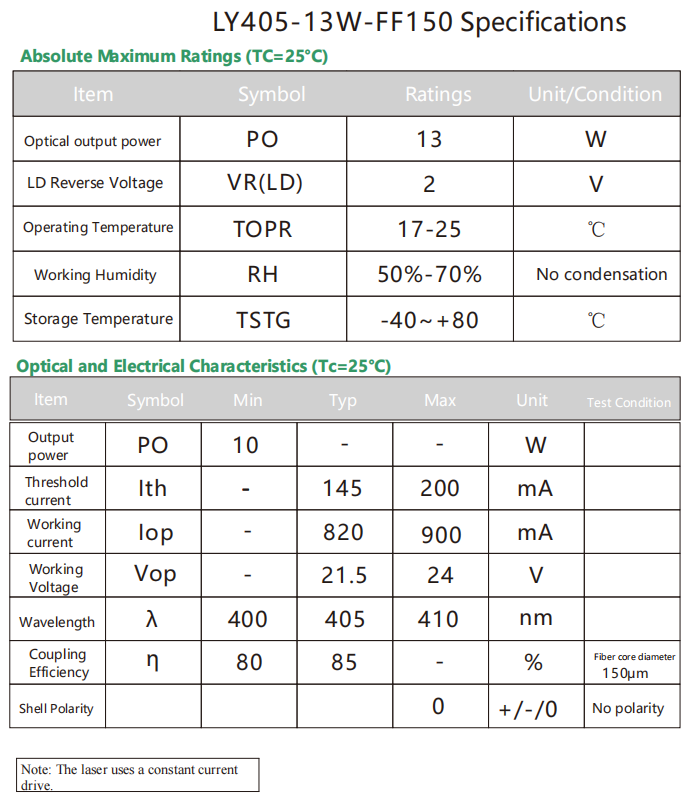

LY405-13W-FF150

The space coupling fiber laser is a light source device that is calibrated through an optical lens group, combined to increase power, and then coupled to an optical fiber.

The 150μm UV 405nm 10W Space Coupling Fiber Laser Module—a heavy-duty near-UV light source engineered for high-throughput industrial precision manufacturing. Tailored for mass-production scenarios including PCB HDI batch lithography, thick-layer UV curing, and large-format SLA 3D printing, this module leverages a 150μm high-power fiber core and upgraded space coupling architecture to deliver unmatched energy density, beam uniformity, and operational stability, far exceeding the performance limits of low-power 5W alternatives.

405nm (±5nm tolerance) near-UV light with 3.06eV photon energy perfectly matches the absorption peak of industrial-grade photoresists, UV-curable adhesives, and polymer composites. It achieves sub-1μm ultra-fine patterning and 1.2mm-thick material one-pass curing—a capability that 5W modules cannot realize even with prolonged irradiation.

10W CW output generates high energy density at the fiber tip, cutting processing cycle time by 80% compared to 5W modules. It supports 24/7 uninterrupted operation for automated production lines, enabling batch fabrication of 200+ microfluidic chips or 50+ large PCB panels per hour.

Ultra-high stability: lower power fluctuation over 24 hours (25°C) and nice wavelength stability, eliminating critical dimension (CD) deviation in high-precision manufacturing and ensuring batch consistency with a yield rate of over 99.7%.

Custom 150μm UV-grade low-OH multimode silica fiber (NA=0.22) is specially optimized for 10W continuous power transmission, with a reinforced fiber cladding design to avoid energy concentration-induced damage. The beam uniformity across the fiber core is higher, completely eliminating hotspots that cause material over-processing or charring.

Upgraded dual-aspheric lens space coupling system achieves ≥85% coupling efficiency. It minimizes optical loss and ensures stable energy delivery even for long-distance fiber transmission (up to 30m), adapting to large-scale factory layout requirements.

| Application Scenario | Core Benefits & Production Efficiency |

|---|---|

| Mass-Production PCB HDI Lithography | Sub-1μm blind via and fine-line patterning; 10W power enables 150mm²/s exposure speed, supporting 800mm×800mm panel batch processing; batch yield rate ≥99.7%. |

| 1.2mm Thick-Layer UV Curing for Automotive Electronics | One-pass curing of 1.2mm-thick UV adhesives and conformal coatings; uniform energy distribution eliminates edge under-curing, ideal for bonding high-power automotive electronic components. |

| High-Speed Large-Format SLA 3D Printing | 20μm layer thickness printing; 10W power cuts print time by 80% vs. 5W modules; compatible with 600mm×600mm build platforms for mass production of industrial structural parts. |

| Batch Fabrication of High-Density Microfluidic Chips | Precision structuring of 3μm-wide microchannels; low thermal impact preserves channel wall smoothness; supports 300+ chips per hour batch processing with consistent performance. |

| 8/12-inch Semiconductor Wafer Surface Activation | UV-induced surface modification of large-size wafers; uniform beam ensures consistent adhesion of solder masks and photoresists; compatible with automated wafer handling systems. |

| Wavelength | 405nm |

| Output Power | >10W |

| Working Voltage | 21.5-24V |

| Fiber Core Diameter | 105um ( The standard product is without fiber, if you need the fiber, please contact our sale person!) |

| Fiber Interface | FC connector /SMA 905 (Customizable) |

| Collimated dot Beam size | / |

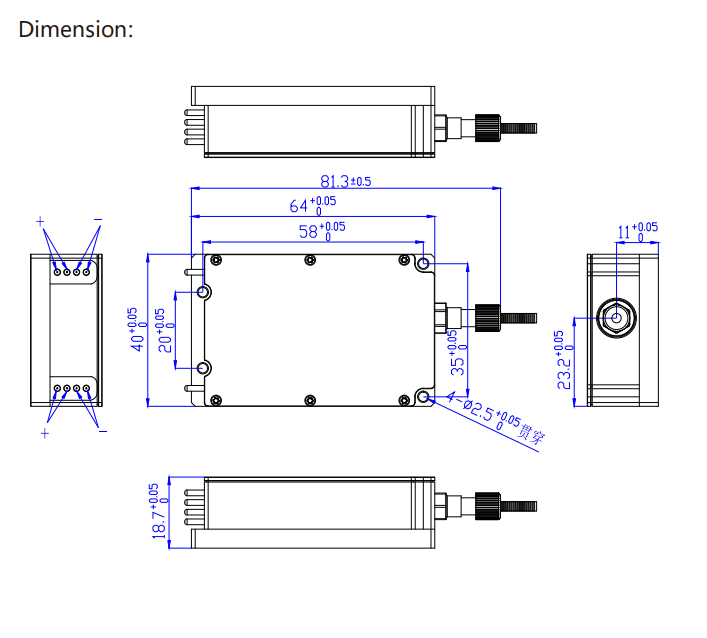

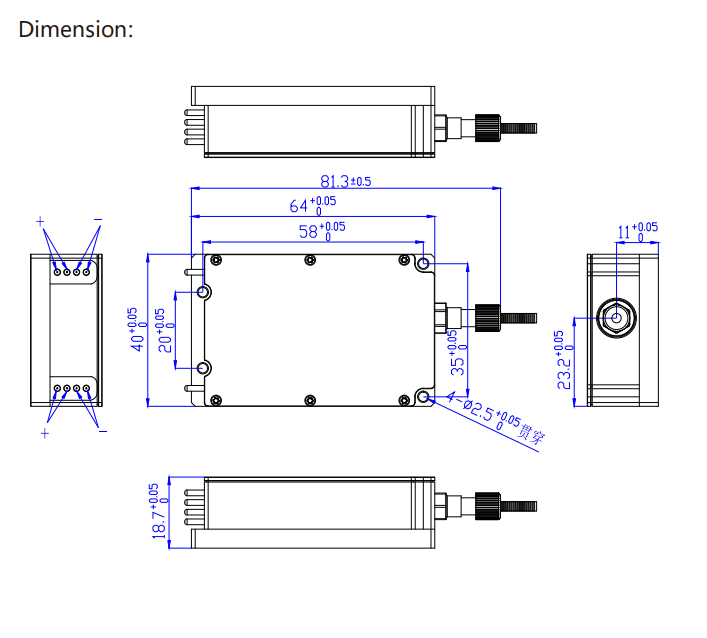

| Housing Size | 64*40*18.7mm (Customizable) |

| Lens | Optical Glass |

| Lifespan | > 10,000 hours |

We have over 15 years of experience with Lasers. We offer professional OEM& ODM service for laser modules!

| Item | Parameter | ||||

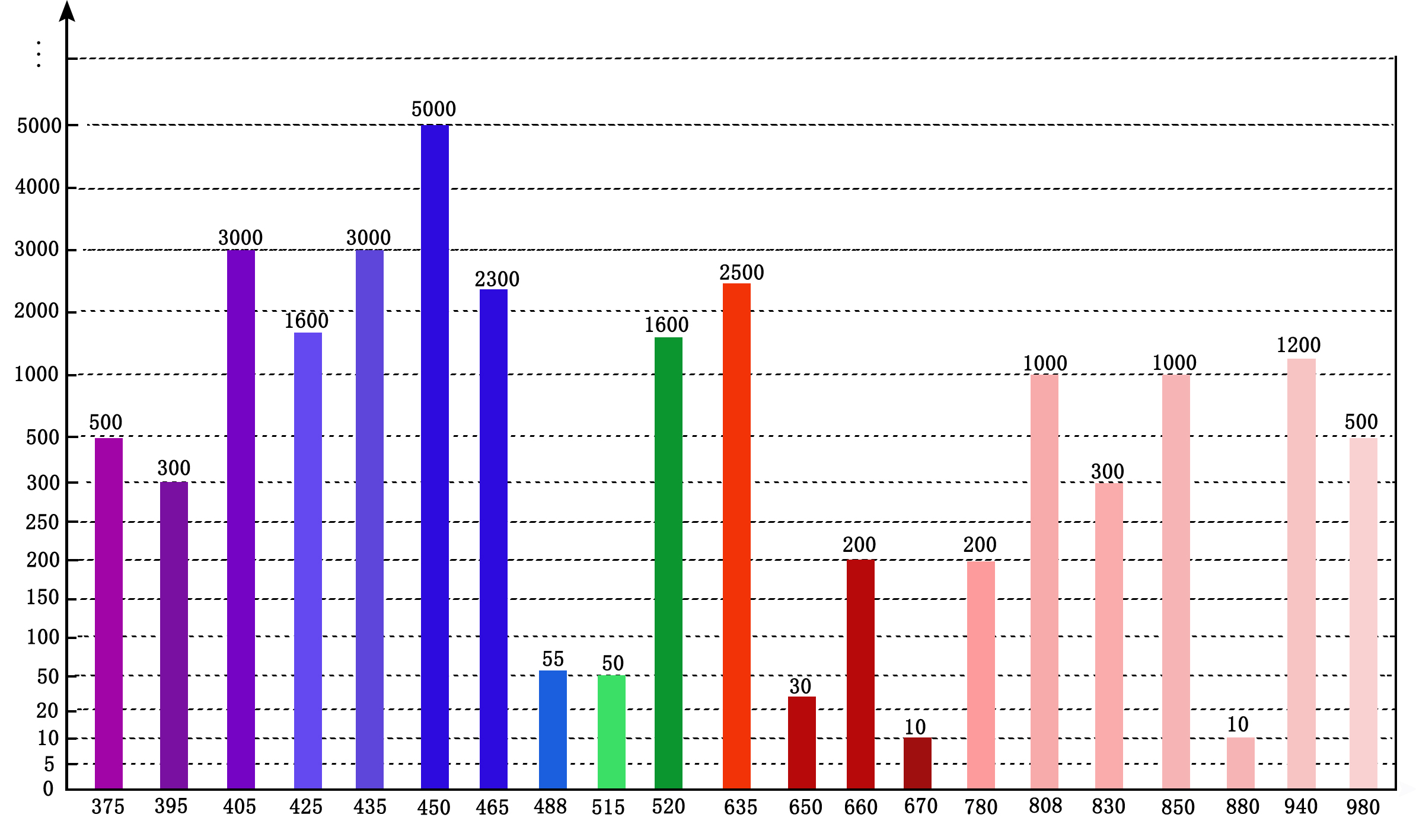

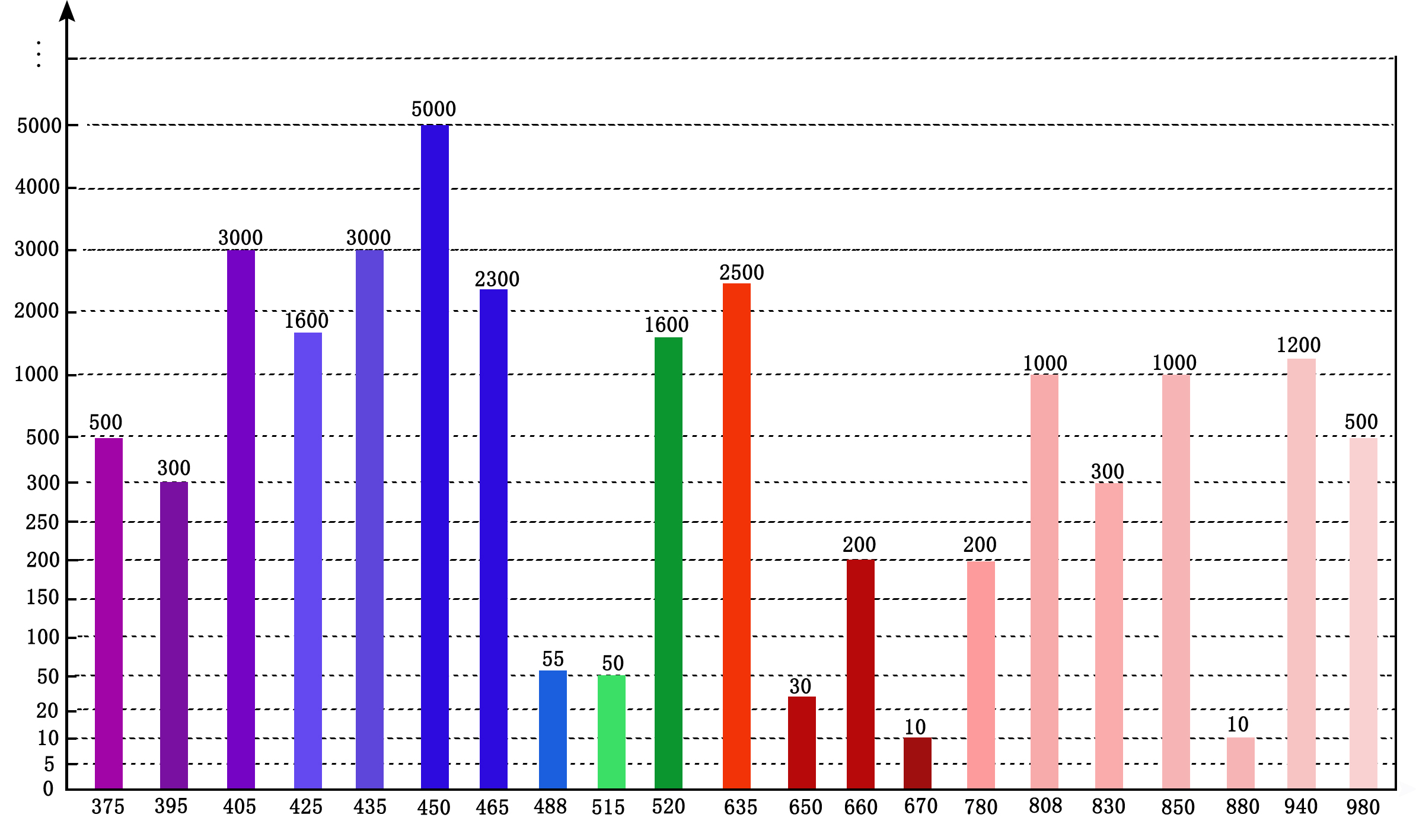

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/80°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||

The space coupling fiber laser is a light source device that is calibrated through an optical lens group, combined to increase power, and then coupled to an optical fiber.

The 150μm UV 405nm 10W Space Coupling Fiber Laser Module—a heavy-duty near-UV light source engineered for high-throughput industrial precision manufacturing. Tailored for mass-production scenarios including PCB HDI batch lithography, thick-layer UV curing, and large-format SLA 3D printing, this module leverages a 150μm high-power fiber core and upgraded space coupling architecture to deliver unmatched energy density, beam uniformity, and operational stability, far exceeding the performance limits of low-power 5W alternatives.

405nm (±5nm tolerance) near-UV light with 3.06eV photon energy perfectly matches the absorption peak of industrial-grade photoresists, UV-curable adhesives, and polymer composites. It achieves sub-1μm ultra-fine patterning and 1.2mm-thick material one-pass curing—a capability that 5W modules cannot realize even with prolonged irradiation.

10W CW output generates high energy density at the fiber tip, cutting processing cycle time by 80% compared to 5W modules. It supports 24/7 uninterrupted operation for automated production lines, enabling batch fabrication of 200+ microfluidic chips or 50+ large PCB panels per hour.

Ultra-high stability: lower power fluctuation over 24 hours (25°C) and nice wavelength stability, eliminating critical dimension (CD) deviation in high-precision manufacturing and ensuring batch consistency with a yield rate of over 99.7%.

Custom 150μm UV-grade low-OH multimode silica fiber (NA=0.22) is specially optimized for 10W continuous power transmission, with a reinforced fiber cladding design to avoid energy concentration-induced damage. The beam uniformity across the fiber core is higher, completely eliminating hotspots that cause material over-processing or charring.

Upgraded dual-aspheric lens space coupling system achieves ≥85% coupling efficiency. It minimizes optical loss and ensures stable energy delivery even for long-distance fiber transmission (up to 30m), adapting to large-scale factory layout requirements.

| Application Scenario | Core Benefits & Production Efficiency |

|---|---|

| Mass-Production PCB HDI Lithography | Sub-1μm blind via and fine-line patterning; 10W power enables 150mm²/s exposure speed, supporting 800mm×800mm panel batch processing; batch yield rate ≥99.7%. |

| 1.2mm Thick-Layer UV Curing for Automotive Electronics | One-pass curing of 1.2mm-thick UV adhesives and conformal coatings; uniform energy distribution eliminates edge under-curing, ideal for bonding high-power automotive electronic components. |

| High-Speed Large-Format SLA 3D Printing | 20μm layer thickness printing; 10W power cuts print time by 80% vs. 5W modules; compatible with 600mm×600mm build platforms for mass production of industrial structural parts. |

| Batch Fabrication of High-Density Microfluidic Chips | Precision structuring of 3μm-wide microchannels; low thermal impact preserves channel wall smoothness; supports 300+ chips per hour batch processing with consistent performance. |

| 8/12-inch Semiconductor Wafer Surface Activation | UV-induced surface modification of large-size wafers; uniform beam ensures consistent adhesion of solder masks and photoresists; compatible with automated wafer handling systems. |

| Wavelength | 405nm |

| Output Power | >10W |

| Working Voltage | 21.5-24V |

| Fiber Core Diameter | 105um ( The standard product is without fiber, if you need the fiber, please contact our sale person!) |

| Fiber Interface | FC connector /SMA 905 (Customizable) |

| Collimated dot Beam size | / |

| Housing Size | 64*40*18.7mm (Customizable) |

| Lens | Optical Glass |

| Lifespan | > 10,000 hours |

We have over 15 years of experience with Lasers. We offer professional OEM& ODM service for laser modules!

| Item | Parameter | ||||

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/80°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||