Views: 0 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

Ever wondered how long laser modules last? Understanding their lifespan is crucial for maximizing efficiency and minimizing costs. Laser modules, essential in various industries, consist of laser diodes, optical elements, and drive electronics. In this post, you'll learn about factors affecting their lifespan, typical longevity, and strategies to extend their life.

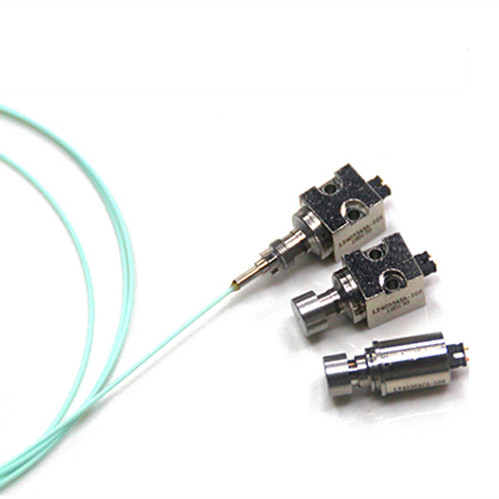

A laser module typically includes three main components:

| Laser Diode | The core element producing coherent light through semiconductor action. It converts electrical energy into laser light. |

| Optical Elements | One or more lenses focus or shape the laser beam for the intended application. |

| Drive Electronics | These control the current supplied to the laser diode, ensuring stable operation and protecting it from damage. |

Together, these parts are housed in a compact, often rugged casing designed to protect internal components and facilitate easy integration into systems.

Laser modules serve diverse roles across industries. Some common applications include:

Alignment and Positioning: Providing visible laser lines or dots for machine setup and calibration.

3D Printing: Curing resins or powders layer by layer to form precise objects.

Measurement and Sensing: Enabling distance measurement, scanning, or environmental monitoring.

Medical Devices: Used in diagnostics, surgery, or therapy.

Industrial Processing: Cutting, welding, or marking materials with high precision.

Each application demands specific laser characteristics such as wavelength, power, and beam shape, influencing the design and selection of the laser module.

The quality of the laser diode is a key factor influencing the lifetime of a laser module. High-quality laser diodes are built with superior semiconductor materials and manufacturing processes, which help reduce defects and improve reliability. These diodes tend to have more stable output power and better resistance to degradation over time. Conversely, lower-quality diodes may degrade faster due to imperfections in the crystal structure or packaging, leading to shorter operational life. Choosing a laser diode from a reputable manufacturer ensures better performance and longevity.

Drive electronics control the current supplied to the laser diode, directly affecting its lifespan. Proper current regulation prevents the diode from being overdriven, which can cause overheating and premature failure. Advanced driver circuits often include features like automatic power control (APC) to maintain consistent output power as the diode ages. Poorly designed or low-quality drive electronics may deliver unstable currents, increasing stress on the diode and accelerating degradation. Therefore, reliable and precise drive electronics are essential for extending laser module life.

Thermal management plays a critical role in maintaining laser module longevity. Laser diodes generate heat during operation, and excessive temperatures can degrade the semiconductor material, reduce efficiency, and cause early failure. Effective heat dissipation methods, such as heat sinks, thermal pads, or active cooling systems, help keep the diode’s temperature within safe limits. Operating a laser module at lower temperatures significantly extends its lifetime; for example, reducing the diode temperature by 10°C can statistically double its lifespan. Without proper thermal management, even high-quality diodes and drive electronics may fail prematurely.

Environmental factors also impact laser module lifetime. Exposure to high humidity, dust, vibration, or corrosive gases can damage internal components or affect optical elements. For instance, moisture ingress can cause corrosion of electrical contacts or optical coatings, while mechanical shocks may misalign lenses or damage the diode. Modules designed for harsh environments often feature ruggedized housings and sealing to protect against these conditions. Selecting a laser module suited to the operating environment helps maintain performance and prolong service life.

Laser modules generally last between 25,000 and 50,000 hours under normal operating conditions. This wide range depends largely on design quality, usage patterns, and environmental factors. For example, a laser module used in a controlled lab environment at moderate power will often approach the higher end of this range. In contrast, modules exposed to harsh conditions or run near maximum power may fall closer to the lower end.

The lifetime figure refers to the point when the laser diode’s output power drops to about 70% of its original level. Beyond this, the laser may still operate but with reduced efficiency and beam quality. Many laser modules include automatic power control to compensate for this gradual drop, maintaining consistent output for longer.

Several mechanisms cause laser modules to degrade over time:

Thermal Stress: Heat is the main enemy. Excessive temperature accelerates semiconductor aging and can cause catastrophic failure. Operating above the recommended temperature range drastically shortens life.

Electrical Overdrive: Supplying current beyond specs stresses the laser diode, leading to quicker wear.

Material Defects: Microscopic flaws in the semiconductor crystal or packaging may grow under operation, causing performance dips.

Environmental Exposure: Moisture, dust, and vibration can damage internal components or misalign optics.

Mechanical Fatigue: Repeated thermal cycling or mechanical shocks may cause cracks or connection failures.

Manufacturers often specify a maximum operating temperature and current to avoid these issues. Staying within these limits greatly extends laser module life.

Heat is the biggest enemy of laser modules. When a laser diode runs, it produces heat that must be removed quickly. Otherwise, the diode’s temperature rises, causing faster wear and possible failure. To manage heat effectively, use heat sinks made of materials with high thermal conductivity like aluminum or copper. These spread heat away from the diode quickly. Thermal pads or pastes improve the contact between the diode and heat sink, enhancing heat transfer. In high-power applications, active cooling such as fans or Peltier devices might be necessary to keep temperatures low.

Keeping the laser diode temperature as low as possible extends its life significantly. For example, lowering the diode temperature by about 10°C can double its expected lifespan. Regularly monitoring the temperature helps catch overheating issues early.

Instead of running a laser module continuously at full power, pulsing it can reduce thermal stress and extend its life. Pulsing means turning the laser on and off rapidly or operating it at lower duty cycles. This reduces the average heat generated, allowing the diode to cool between pulses. Pulsed operation also reduces the chance of electrical overstress, which can damage the diode.

Many industrial and medical lasers use pulsing to balance power needs and longevity. Pulsing can also improve the laser’s performance in applications requiring precise timing or synchronization.

Operating laser modules within specified limits is crucial. Avoid driving the laser diode beyond its recommended current or voltage. Overdriving causes excess heat and accelerates degradation. Use drive electronics with features like automatic power control (APC) that adjust current to maintain stable output as the diode ages.

Environmental conditions matter too. Protect laser modules from dust, moisture, and vibration. These can damage optics or electronics and reduce lifetime. Choose modules with rugged housings or sealing if used in harsh environments.

Finally, avoid rapid temperature changes. Thermal cycling can cause mechanical stress and cracks inside the module. Steady operating conditions help maintain alignment and performance.

Tip: Implement robust heat sinking and consider pulsed operation to keep laser diodes cool, significantly extending laser module lifetime while maintaining stable output.

When selecting laser modules, balancing cost against lifetime is crucial. High-quality laser diodes and advanced drive electronics often come with a higher upfront price but deliver longer service life and better reliability. These modules tend to reduce total cost of ownership by minimizing replacement frequency and maintenance needs. Conversely, lower-cost modules may be attractive initially but can have shorter lifespans, leading to more frequent replacements and potential downtime.

In some applications, especially where laser modules are easy to access and replace, opting for a less expensive module with a shorter lifetime might be economically sensible. For instance, if the environment is benign and the laser is not driven at maximum power, the trade-off can work well. However, in critical or hard-to-access installations, investing in longer-lasting modules reduces operational interruptions and ensures consistent performance.

Manufacturers often provide detailed specifications and lifetime data to help buyers evaluate these trade-offs. It's important to consider not just purchase cost but also installation, downtime, and maintenance expenses over the module’s expected life.

Downtime costs can quickly outweigh savings from cheaper laser modules. Easy replacement procedures and modular designs help minimize downtime, improving overall system availability. Some laser modules feature plug-and-play connectors and standardized mounting, allowing technicians to swap units quickly without specialized tools or calibration.

In environments where continuous operation is vital, designing systems for rapid laser module replacement is a smart strategy. This might include keeping spare modules on hand and training staff in quick-change procedures. Reducing the time a system is offline prevents production losses and maintains customer satisfaction.

On the other hand, if replacement is difficult or requires system disassembly, choosing a laser module with a longer expected lifetime becomes more critical. This lowers the frequency of replacements and associated downtime.

Ultimately, understanding the balance between module cost, expected lifetime, and replacement ease helps businesses optimize their laser system investments for reliability and cost-efficiency.

Laser modules typically last between 25,000 and 50,000 hours, influenced by diode quality, drive electronics, thermal management, and environmental conditions. Effective thermal management and pulsing techniques can extend their lifespan. When selecting laser modules, consider the cost versus lifetime trade-offs and ease of replacement to minimize downtime. Blueuniverse Laser offers high-quality laser modules with advanced features, ensuring longevity and reliability. Their products provide excellent value by reducing maintenance costs and maximizing operational efficiency.

A: A laser module is a compact device that includes a laser diode, optical elements, and drive electronics, used for applications like alignment, 3D printing, and medical devices.

A: A laser module typically lasts between 25,000 and 50,000 hours, depending on quality, usage, and environmental conditions.

A: Effective thermal management prevents overheating, which can degrade laser module performance and shorten its lifespan.

A: Use high-quality components, ensure proper thermal management, and operate within recommended limits to extend the laser module's life.

A: The cost of a laser module depends on diode quality, drive electronics, thermal management features, and expected lifespan.