Views: 0 Author: Site Editor Publish Time: 2025-09-17 Origin: Site

In the field of vision lasers, uniform line lasers, with their unique advantages, are an ideal choice for numerous applications. The following is a detailed introduction:

Professional Manufacturer of the uniform line lasers : Dongguan Blueuniverse Laser Co., Ltd.

High Uniformity: Utilizing special optical designs, such as Powell prisms, the laser beam achieves a power density uniformity of over 80% when forming a line. This means that the light intensity is relatively consistent across the entire line, eliminating bright spots in the middle and dark spots at the edges. This provides a stable and reliable light source for applications such as visual inspection.

Clear and Straight Lines: These lasers produce exceptionally sharp lines with minimal straightness error, typically ≤0.1%. Their high degree of collimation provides a precise reference for various applications requiring precise marking, ensuring that vision systems can accurately identify and measure the position and shape of lines.

Multiple Wavelength Options: Common wavelengths include 405nm, 450nm, 488nm, 520nm, 635nm, and 650nm. Different wavelengths are suitable for different application scenarios and test objects, allowing users to select the optimal inspection result based on their specific needs.

Compact, Lightweight, and Easy to Adjust: These lasers are typically small and lightweight, making them easy to install and integrate into various devices. They can also adjust parameters like power and divergence angle to accommodate varying working distances and line lengths, offering simple operation and high flexibility.

Stable and Reliable Performance: They offer excellent stability, with power stability typically less than 5%. They also feature overheating and electrostatic protection, ensuring long-term stable operation under diverse environmental conditions and a long service life, typically exceeding 10,000 hours.

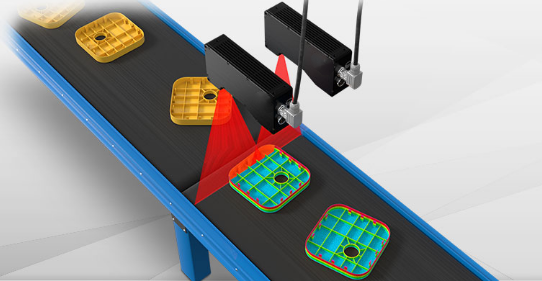

3D Scanning Measurement: These lasers project a clear, uniform line onto the surface of an object. Vision systems capture the deformation of the line on the surface, enabling precise measurement of the object's three-dimensional shape and dimensions. These lasers are widely used in industrial product inspection, cultural relic preservation, and reverse engineering.

Machine Vision Inspection: These lasers provide clear reference lines for edge detection, dimensional measurement, and defect detection. For example, on electronic component production lines, they are used to verify that component shape and dimensions meet standards and detect surface defects, improving inspection accuracy and efficiency.

Industrial positioning and alignment: In industrial production, it is used for equipment installation and commissioning, production line positioning and calibration, etc. In mechanical processing, it helps workers quickly and accurately determine the processing position to ensure processing accuracy.

![]()