Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

Ever wondered how to ensure your laser module performs optimally? Testing is crucial for reliability and safety. In this article, we'll explore why testing is important and introduce various techniques to effectively test laser modules. You'll learn essential tools, safety precautions, and troubleshooting tips to ensure accurate results.

Before testing a laser module, gather all necessary tools and equipment to ensure accurate and safe testing. Here’s what you typically need:

Multimeter: A digital multimeter with diode test mode is essential for checking electrical connections and diode functionality.

Optical Power Meter: Measures the laser’s output power to evaluate performance.

Test Load: Simulates the laser diode load during setup, protecting the actual diode from damage.

Power Supply: A stable DC power supply to power the laser module and associated testing equipment.

Connection Cables and Probes: Quality cables and probes ensure reliable connections.

Safety Equipment: Laser safety goggles appropriate for the laser's wavelength and power level.

Screwdrivers and Pliers: For connecting and securing cables and components.

Oscilloscope (optional): Useful for monitoring modulation signals during advanced testing.

Having these tools ready avoids interruptions and helps maintain test accuracy.

Testing laser modules involves potential hazards, especially from laser radiation and electrical components. Follow these safety guidelines:

Wear Laser Safety Goggles: Always wear goggles rated for the laser’s specific wavelength and power to protect your eyes.

Avoid Direct Eye Exposure: Never look directly into the laser beam or its reflection.

Control the Test Environment: Conduct tests in a controlled area with warning signs to prevent accidental exposure.

Disconnect Power When Not Testing: Always turn off and unplug equipment before making or changing connections.

Use Insulated Tools: Prevent electrical shocks by using insulated tools and handling cables carefully.

Check for Proper Grounding: Ensure the test setup is properly grounded to avoid electrical hazards.

Follow Manufacturer Guidelines: Adhere to the laser module’s datasheet and safety instructions.

Keep Flammable Materials Away: Laser beams can ignite materials; maintain a clean workspace.

Observing these precautions reduces risk and ensures a safe testing process.

Before you start testing the laser module itself, make sure all cables and connectors are in good condition. Faulty or loose cables can cause intermittent or complete failure of the laser module. Here’s how to check them:

Inspect Cables: Look for any visible damage like cuts, frays, or kinks. Damaged cables should be replaced immediately.

Check Connectors: Ensure that connectors are clean, free from corrosion, and not bent or broken.

Secure Connections: Plug connectors firmly into their ports. Loose connections can cause power loss or erratic behavior.

Avoid Sharp Bends: Cables should not be bent sharply, as this can damage internal wires and insulation.

Retaining Screws: If connectors have screws or clips, make sure they are tightened to prevent disconnections during operation.

Doing a thorough check of cables and connectors prevents many common issues and lays a solid foundation for accurate laser testing.

Laser modules are sensitive devices that require correct wiring and orientation to function properly. Here’s what to keep in mind:

Follow Pinouts: Check the laser module datasheet or manual for the correct pin configuration. Connecting the module incorrectly can damage it.

Polarity Matters: The laser diode inside the module has positive (anode) and negative (cathode) terminals. Reverse polarity can cause failure.

Connector Orientation: Some connectors are keyed to fit only one way. Don’t force a connector if it doesn’t fit easily.

Confirm Power Supply Compatibility: Ensure the voltage and current ratings of your power supply match the laser module specifications.

Use Multimeter to Verify: Before powering the module, use a multimeter to check continuity and correct wiring of cables.

Proper connection and orientation reduce the risk of damage and ensure the module operates as expected during testing.

Tip: Always label your cables and connectors during setup to avoid confusion and ensure consistent, correct connections every time you test your laser modules.

When testing a laser module’s diode using a multimeter, you have two primary modes: Diode Test mode and Resistance mode.

| Diode Test Mode | This is the preferred method. It applies a small voltage to the diode and measures the forward voltage drop. A good silicon diode usually shows a voltage drop between 0.5 to 0.8 volts. When reverse-biased, the multimeter should display "OL" (open loop), indicating no current flow. This mode helps confirm if the diode is functioning correctly. |

| Resistance Mode | This mode measures the resistance of the diode but is less reliable for diode testing. It can give false readings if the diode is still connected in a circuit. Resistance mode is mainly useful to check if a diode is definitely bad after a diode test suggests a fault. For a good diode, forward-biased resistance is high (from 1,000 Ω to 10 MΩ), and reverse-biased resistance reads as open loop. |

Follow these steps to test your laser diode safely and accurately:

Power Off and Discharge: Ensure all power to the circuit is off. Discharge any capacitors to avoid stored voltage affecting readings.

Set Multimeter to Diode Test Mode: Turn the dial to the diode symbol. If your multimeter lacks this mode, use resistance mode but be cautious.

Connect Test Leads: Attach the red (positive) lead to the diode’s anode and the black (negative) lead to the cathode.

Record Forward Voltage: Observe and note the voltage drop displayed. A typical laser diode should show a forward voltage around 1.8 to 2.2 volts (this varies by diode type).

Reverse Leads: Swap the leads—red to cathode, black to anode—and check the reading again. It should show "OL," indicating the diode blocks current in reverse.

Interpret Results:

Good Diode: Forward voltage within expected range, reverse reading "OL."

Open Diode: Both directions show "OL," meaning no current flows.

Shorted Diode: Both directions show low voltage drop or low resistance.

Test Outside Circuit if Needed: If readings are unclear, remove one end of the diode from the circuit to avoid interference.

Testing your laser diode this way helps identify faulty components before powering the module, preventing damage.

One of the key steps to evaluate a laser module’s performance is measuring its optical power output. This tells you how much light energy the laser emits, which directly affects its effectiveness in applications.

To measure optical power:

Use a calibrated optical power meter designed for the laser’s wavelength.

Position the sensor directly in the laser beam path, avoiding reflections or scattering.

Turn on the laser module and allow it to stabilize for a few seconds.

Record the power reading displayed on the meter.

Compare this reading to the laser module’s specified output power in its datasheet.

If the measured power is significantly lower than expected, it could indicate:

Degraded or damaged laser diode.

Dirty or obstructed optics.

Incorrect current or voltage supplied to the laser.

Regular power output checks help maintain consistent laser performance and identify issues early.

Monitoring electrical parameters such as voltage and current is crucial for safe and effective laser operation.

Voltage: Use a multimeter to measure the voltage across the laser diode terminals while it is operating. Check that it matches the recommended operating voltage in the datasheet.

Current: The laser diode current should be monitored carefully, as exceeding the maximum rated current can permanently damage the diode.

To assess these parameters:

Connect the laser module to a stable power supply.

Use a multimeter set to measure DC voltage to check voltage across the diode.

Use a current meter or a multimeter in series to measure current flowing through the diode.

Confirm that both voltage and current remain within manufacturer-specified limits during operation.

If voltage or current readings are abnormal, it may cause performance issues or damage. For example, a voltage drop below the expected range can indicate internal damage, while excessive current may suggest a faulty driver or wiring.

Connection issues are a common cause of laser module failures or poor performance. To troubleshoot these problems:

Inspect Cables and Connectors: Look for loose connectors, damaged cables, or bent pins. Replace any damaged cables immediately.

Ensure Firm Connections: Unplug and replug cables to confirm tight connections. Loose cables often cause intermittent laser operation.

Check Cable Orientation: Verify correct cable orientation following the laser module’s datasheet. Reversed connections can prevent the laser from firing or damage it.

Look for Short Circuits: Use a multimeter in continuity or buzz mode to check for shorts between ground and signal lines. A short circuit may require replacing the module.

Avoid Cable Stress: Prevent sharp bends or kinks that could damage internal wires or insulation.

Confirm Connector Cleanliness: Dirt or corrosion on connectors can cause poor electrical contact. Clean connectors gently if needed.

By methodically checking these connection points, you can often restore laser module function without replacing parts.

Voltage irregularities and firmware problems also cause laser modules to malfunction. Here's how to address them:

Measure Supply Voltage: Use a multimeter to verify the power supply voltage matches the laser module’s specified range. Undervoltage or overvoltage can prevent laser emission or damage components.

Check Motherboard and Adapter Indicators: Confirm power indicators on the motherboard and adapter are lit during operation. A failure may indicate faulty hardware.

Test Output Voltage to Laser Module: Measure voltage between the motherboard and laser module during operation. It should match expected values (e.g., 12V or 24V depending on model).

Update Firmware: Incorrect or outdated firmware can cause the laser not to fire or cause motor lockups. Follow manufacturer instructions to upgrade firmware to the latest version.

Verify Software Settings: Ensure processing parameters, such as laser power settings, are correctly configured in the control software. Low or zero power settings prevent laser firing.

Monitor Laser Module Indicators: Check onboard LEDs and fans. For example, some modules have fans that should run during operation; failure may indicate hardware issues.

Check for Short Circuits with a Multimeter: If the laser module still does not fire, test for short circuits between relevant pins using the multimeter’s buzz mode.

If these steps fail, contact technical support with detailed troubleshooting notes for further assistance.

A test load is a crucial tool when setting up or troubleshooting laser modules. It acts as a safe stand-in for the actual laser diode, mimicking its electrical characteristics without risking damage to the real device. This approach offers several benefits:

Protects the Laser Diode: Laser diodes are sensitive and costly. Using a test load helps avoid accidental overcurrent or voltage spikes that could destroy the diode during setup.

Familiarizes Operators: It allows you to understand how the laser driver or controller responds to changes in settings, such as current limits or modulation inputs.

Simplifies Troubleshooting: When issues arise, a test load helps isolate problems to the driver or controller, rather than the laser diode itself.

Verifies Equipment Functionality: Ensures that the power supply, driver, and monitoring instruments work correctly before connecting the actual laser.

Enables Safe Limit Setting: You can safely adjust current and power limits and observe system behavior without risking damage.

Using a test load is a best practice to increase confidence and reduce downtime during laser module setup.

Laser diode drivers often support two main operation modes for testing: Constant Current mode and Constant Power mode. Setting up a test load differs slightly between these modes.

In Constant Current mode, the driver maintains a fixed current through the load. To set up:

Connect the Test Load: Attach the test load between the laser diode anode (LDA) and cathode (LDC) terminals on the driver.

Set Driver to Constant Current: Switch the driver to Constant Current mode.

Monitor Current: Connect a multimeter set to voltage mode between the current monitor (IMON) pin and ground (GND).

Adjust Current Limits: Turn the Current Limit trimpot fully off (usually by rotating fully counterclockwise). Then turn the Current Setpoint trimpot fully on (fully clockwise).

Power the System: Attach a 5 V power supply and enable the driver.

Set Desired Current: Slowly increase the Current Limit trimpot until the IMON voltage corresponds to your target current (use the driver datasheet for transfer function details).

Fine-Tune Setpoint: Adjust the Current Setpoint trimpot down until the current stabilizes at the desired operating point.

Optional Modulation: Connect a signal generator to the analog modulation input if needed, and use an oscilloscope to observe current variations.

Once complete, return trimpots to the off position before connecting the real laser diode.

Constant Power mode uses feedback from a photodiode to maintain a fixed optical output power. To set up:

Attach Test Load: Connect the test load to LDA, LDC, and the Photodiode Anode (PDA) terminals.

Set Driver to Constant Power: Switch the driver to Constant Power mode and select the appropriate photodiode current range.

Monitor Power Feedback: Connect a multimeter between the power monitor (PMON) pin and ground.

Power the System: Attach a 5 V power supply and enable the driver.

Adjust Settings: Use trimpots and datasheet transfer functions to set the simulated photodiode current, ensuring PMON voltage matches expected values.

Complete Setup: After testing, return trimpots to off positions before connecting the actual laser diode.

This setup helps verify photodiode feedback circuits and ensures the driver maintains stable power output.

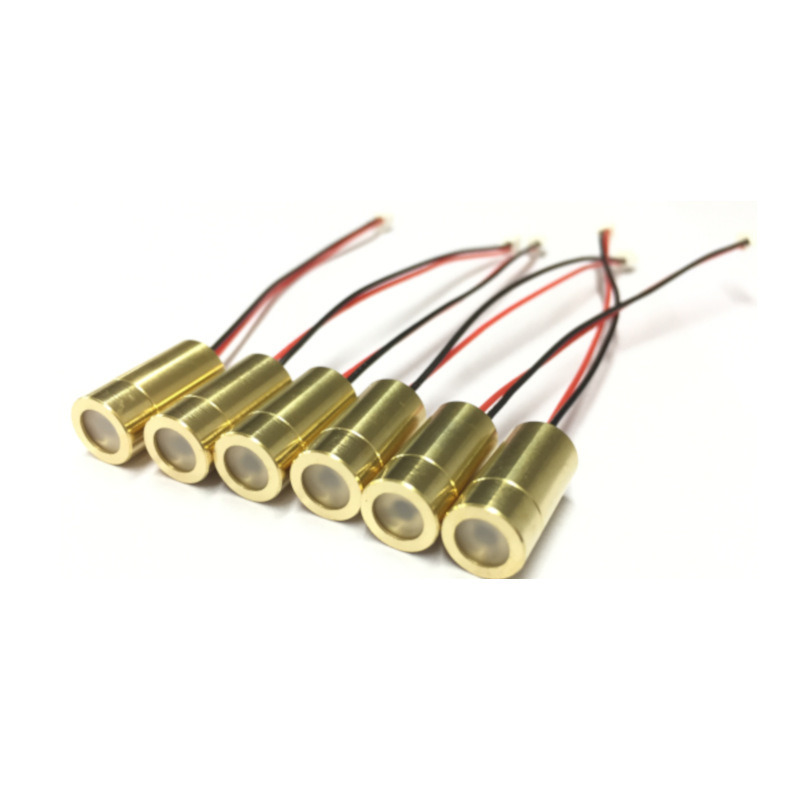

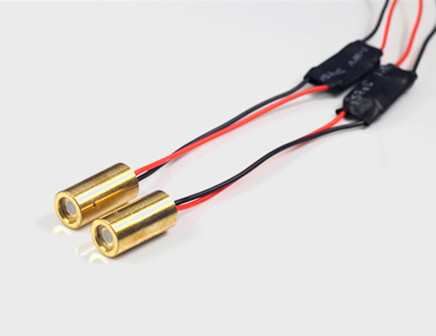

Testing a laser module involves gathering essential tools, ensuring safety, and checking connections. Use a multimeter for diode tests and evaluate optical power output. Employ test loads for setup, protecting the diode. Follow these steps to ensure accurate and safe testing. Blueuniverse Laser offers high-quality laser modules with unique features, providing value and reliability for your testing needs.

A: A laser module is a compact device that emits laser light, typically comprising a laser diode, driver, and optics. It is used in various applications for precision and efficiency.

A: To test a laser module safely, gather essential tools like a multimeter, optical power meter, and safety goggles. Follow manufacturer guidelines and ensure proper connections to prevent damage.

A: A test load mimics the laser diode's electrical characteristics, allowing safe setup and troubleshooting without risking damage to the actual laser module.

A: Measuring optical power output helps evaluate a laser module's performance and effectiveness, ensuring it meets application requirements and identifying potential issues early.