| Availability: | |

|---|---|

| Quantity: | |

LY3710-A

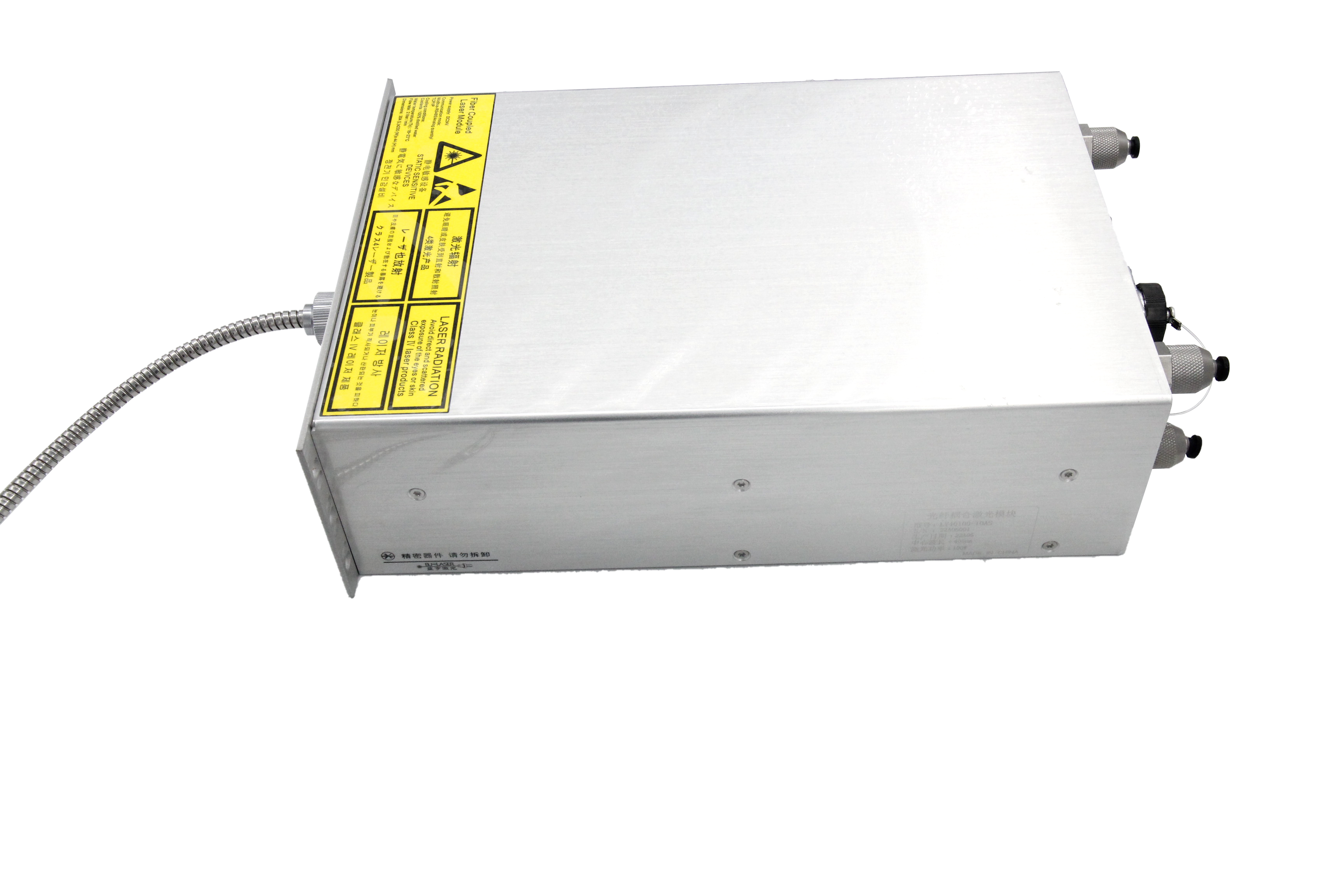

The High Power 10W 375nm Fiber Coupled Laser Module—a cutting-edge UV light source optimized for advanced lithography machines, including laser direct imaging (LDI) systems, maskless aligners, and semiconductor photolithography equipment. Combining 375nm near-UV wavelength’s superior photoresist absorption, 10W high-power output, and precision fiber coupling technology, this module delivers unmatched exposure speed, resolution, and stability for microfabrication of semiconductors, PCBs, LED chips, and microfluidic devices.

375nm (±2nm tolerance) near-UV light offers 50–80% higher absorption efficiency in g-line/h-line photoresists compared to 405nm violet lasers, enabling sub-micron resolution (down to 0.5μm) and sharper pattern edges for semiconductor and PCB manufacturing.

The wavelength falls within the optimal absorption window for most commercial photoresists, minimizing exposure energy requirements and reducing heat-induced pattern distortion.

Ultra-narrow spectral linewidth (≤5nm FWHM) ensures consistent photoresist response across the entire exposure field, eliminating color shift-induced pattern variations.

10W CW output power via 105μm/200μm multi-mode fiber (customizable) delivers high energy density at the exposure plane, reducing exposure time by 60% compared to 5W modules for high-volume production lines.

Integrating with a water cooling system, the power stability ≤±0.5% over 8 hours ensures uniform exposure across large substrates, critical for maintaining consistent pattern quality in batch manufacturing.

0–100% PWM modulation with microsecond-level response time enables precise grayscale lithography and dynamic exposure control for 3D microstructures.

High-efficiency fiber coupling (≥85%) minimizes optical loss, ensuring maximum power transmission to the lithography machine’s scanning system.

2–10m fiber length options (UV-grade silica fiber with anti-reflective coating) provide flexible integration into complex lithography optical paths without compromising beam quality.

RS485 digital communication interface enables real-time monitoring and adjustment of power, temperature, and modulation parameters, seamlessly integrating with lithography machine controllers.

Modular design with standard fiber pigtail connectors (FC/PC, SMA905) fits most commercial lithography machines, including Raith PicoMaster, Heidelberg MLA150, and domestic LDI systems.

| Wavelength | 375nm |

| Output Power | >10W |

| Working Voltage | 24V |

| Fiber Core Diameter | 105um |

| Fiber Interface | FC connector /SMA 905 (Customizable) |

| Collimated dot Beam size | / |

| Housing Size | 354*207*44mm (Customizable) |

| Lens | Optical Glass |

| Lifespan | > 10,000 hours |

Note: It is designed with water cooling systems inside. The driver inside is already integrated with RS-485 communication software.

As it is a fiber-bundled laser, we can increase or decrease the quantity of the laser diode inside to change the power so that the power can be from 1W to 100W. And the fiber type and length also can be selected by you!

We have over 15 years of experience with Lasers. We offer professional OEM& ODM service for laser modules!

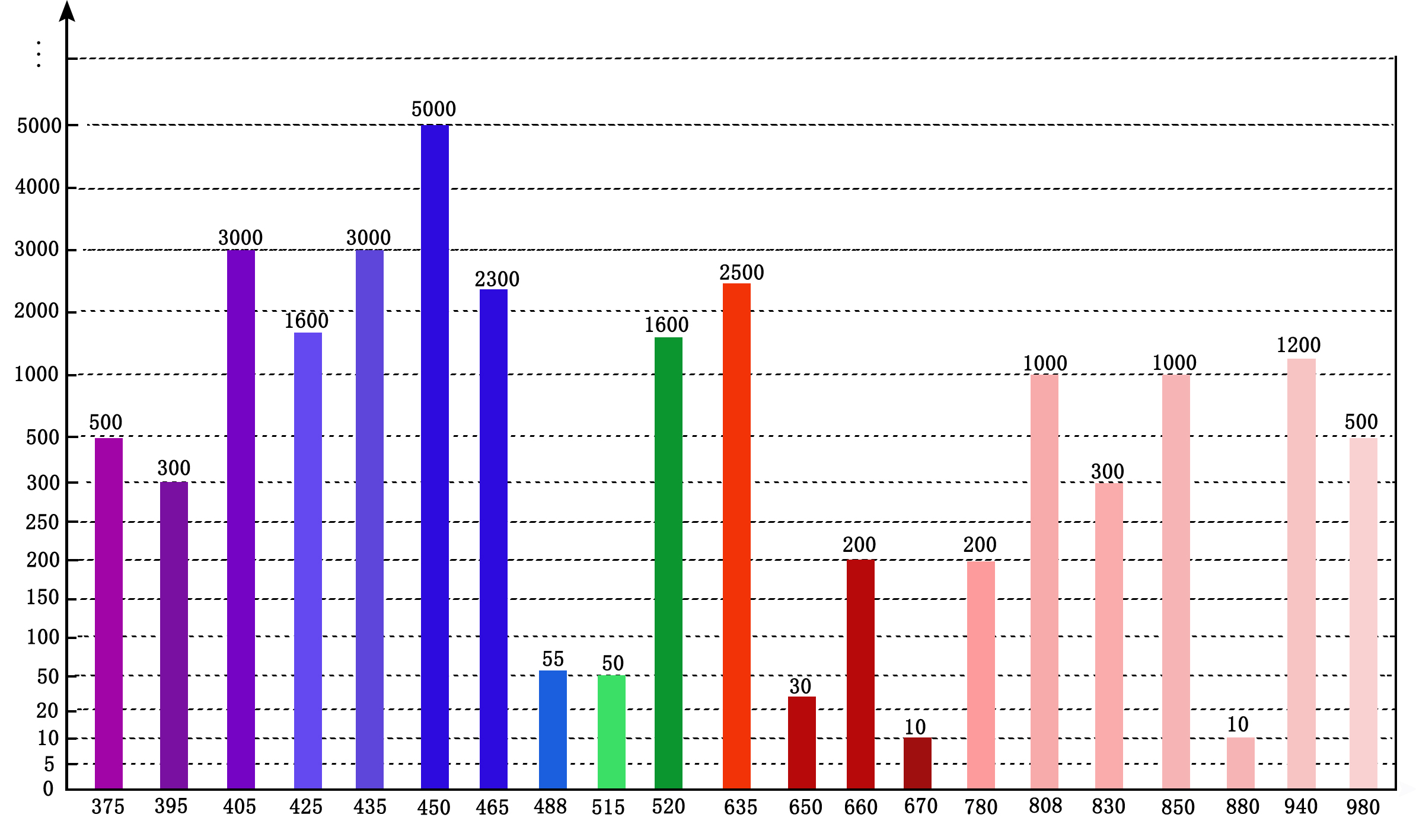

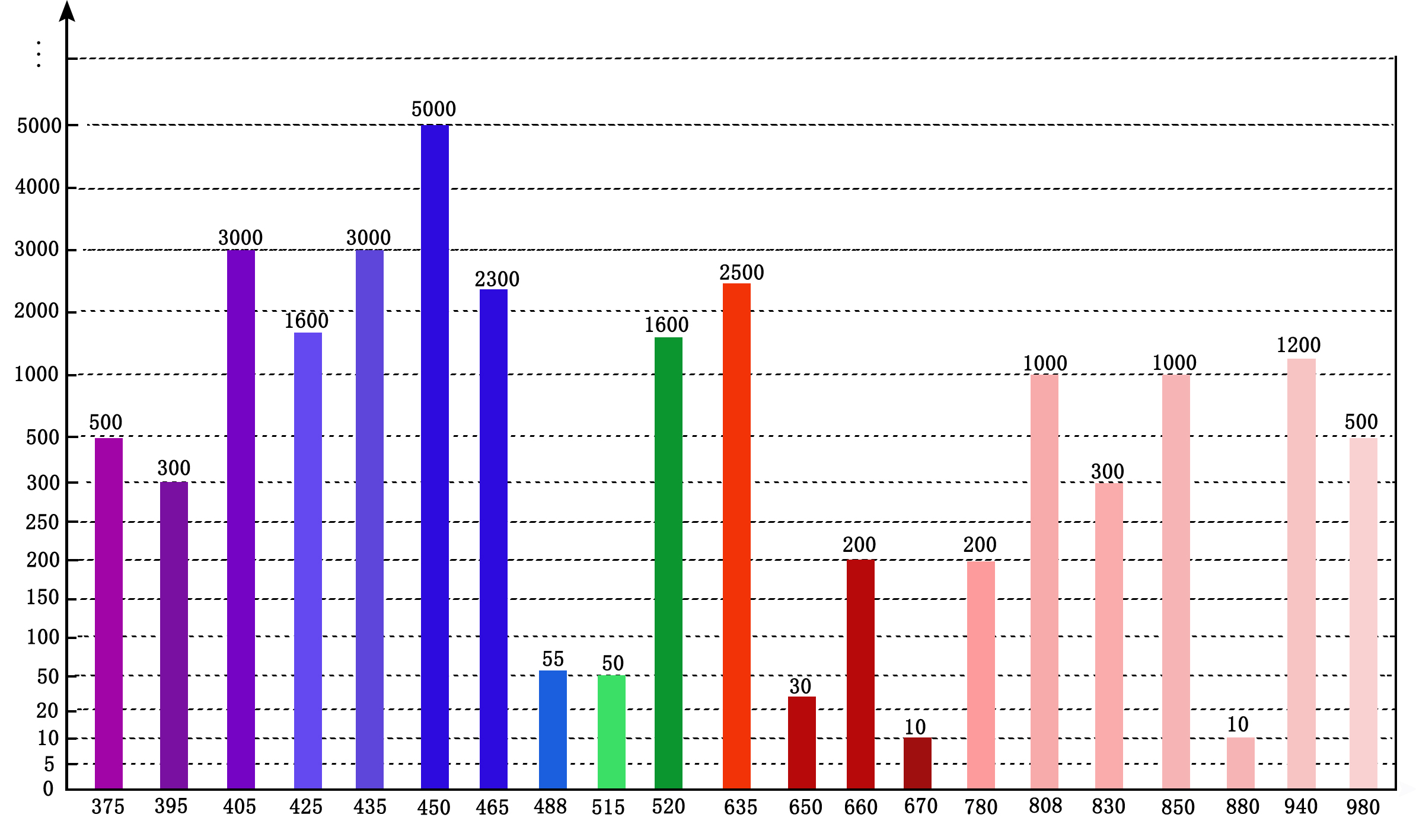

| Item | Parameter | ||||

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/80°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||

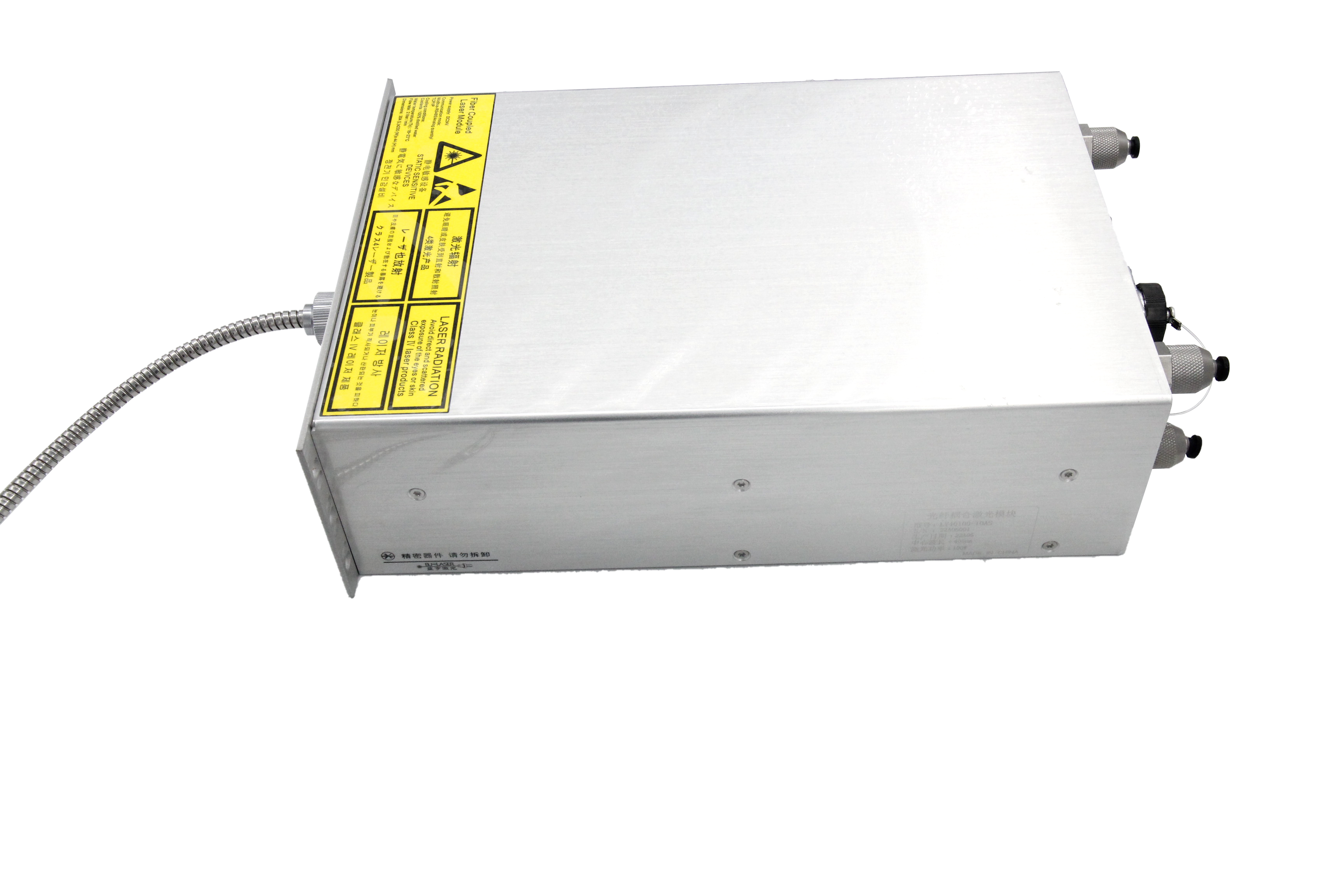

The High Power 10W 375nm Fiber Coupled Laser Module—a cutting-edge UV light source optimized for advanced lithography machines, including laser direct imaging (LDI) systems, maskless aligners, and semiconductor photolithography equipment. Combining 375nm near-UV wavelength’s superior photoresist absorption, 10W high-power output, and precision fiber coupling technology, this module delivers unmatched exposure speed, resolution, and stability for microfabrication of semiconductors, PCBs, LED chips, and microfluidic devices.

375nm (±2nm tolerance) near-UV light offers 50–80% higher absorption efficiency in g-line/h-line photoresists compared to 405nm violet lasers, enabling sub-micron resolution (down to 0.5μm) and sharper pattern edges for semiconductor and PCB manufacturing.

The wavelength falls within the optimal absorption window for most commercial photoresists, minimizing exposure energy requirements and reducing heat-induced pattern distortion.

Ultra-narrow spectral linewidth (≤5nm FWHM) ensures consistent photoresist response across the entire exposure field, eliminating color shift-induced pattern variations.

10W CW output power via 105μm/200μm multi-mode fiber (customizable) delivers high energy density at the exposure plane, reducing exposure time by 60% compared to 5W modules for high-volume production lines.

Integrating with a water cooling system, the power stability ≤±0.5% over 8 hours ensures uniform exposure across large substrates, critical for maintaining consistent pattern quality in batch manufacturing.

0–100% PWM modulation with microsecond-level response time enables precise grayscale lithography and dynamic exposure control for 3D microstructures.

High-efficiency fiber coupling (≥85%) minimizes optical loss, ensuring maximum power transmission to the lithography machine’s scanning system.

2–10m fiber length options (UV-grade silica fiber with anti-reflective coating) provide flexible integration into complex lithography optical paths without compromising beam quality.

RS485 digital communication interface enables real-time monitoring and adjustment of power, temperature, and modulation parameters, seamlessly integrating with lithography machine controllers.

Modular design with standard fiber pigtail connectors (FC/PC, SMA905) fits most commercial lithography machines, including Raith PicoMaster, Heidelberg MLA150, and domestic LDI systems.

| Wavelength | 375nm |

| Output Power | >10W |

| Working Voltage | 24V |

| Fiber Core Diameter | 105um |

| Fiber Interface | FC connector /SMA 905 (Customizable) |

| Collimated dot Beam size | / |

| Housing Size | 354*207*44mm (Customizable) |

| Lens | Optical Glass |

| Lifespan | > 10,000 hours |

Note: It is designed with water cooling systems inside. The driver inside is already integrated with RS-485 communication software.

As it is a fiber-bundled laser, we can increase or decrease the quantity of the laser diode inside to change the power so that the power can be from 1W to 100W. And the fiber type and length also can be selected by you!

We have over 15 years of experience with Lasers. We offer professional OEM& ODM service for laser modules!

| Item | Parameter | ||||

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/80°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||