| Availability: | |

|---|---|

| Quantity: | |

LY4040-3708-AD

The 2IN1 405nm 40W & 375nm 8W Dual Wavelength UV Fiber Coupled Laser Module—a high-power, multi-functional optical solution engineered for advanced microfabrication, semiconductor processing, PCB HDI (High-Density Interconnect) dual-process lithography, and UV-curable material manufacturing. Combining the high-efficiency processing capability of 405nm violet light and the ultra-high-resolution patterning advantage of 375nm near-UV light, this module delivers 48W total output power with independent wavelength control, enabling one-module integration of multiple precision processing workflows and reducing equipment investment costs.

375nm 8W Near-UV Wavelength: Targets high-resolution patterning scenarios—aligns with the absorption peak of g-line/h-line photoresists, enabling sub-1μm ultra-fine feature fabrication (e.g., semiconductor MEMS devices, microfluidic chip channels) with minimal heat-affected zones (HAZ ≤0.5μm). Ultra-narrow spectral linewidth (≤3nm FWHM) ensures consistent photoresist response, critical for critical dimension (CD) control in advanced manufacturing.

405nm 40W Violet Wavelength: Optimized for high-throughput processing—achieves 3–5x higher absorption efficiency on acrylate-based photoresists, UV-curable adhesives, and polymer composites than 375nm light, enabling single-pass fast exposure of 600mm×600mm PCB panels and rapid curing of thick conformal coatings. 40W high power cuts processing time by 70% compared to single-wavelength 10W modules.

Independent Wavelength Control: Both wavelengths support separate on/off switching and 0–100% PWM modulation, enabling flexible switching between high-resolution patterning (375nm) and high-speed processing (405nm) without reconfiguring the optical path.

Total 48W CW output power (40W+8W) delivers combined energy density ≥50,000mW/cm² at the fiber tip, supporting high-volume batch production of complex components that require both fine patterning and rapid processing.

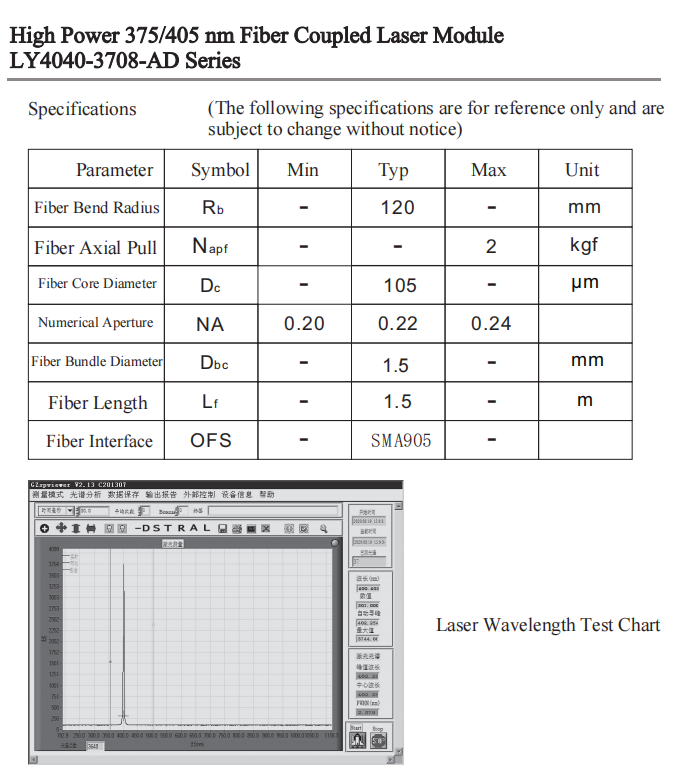

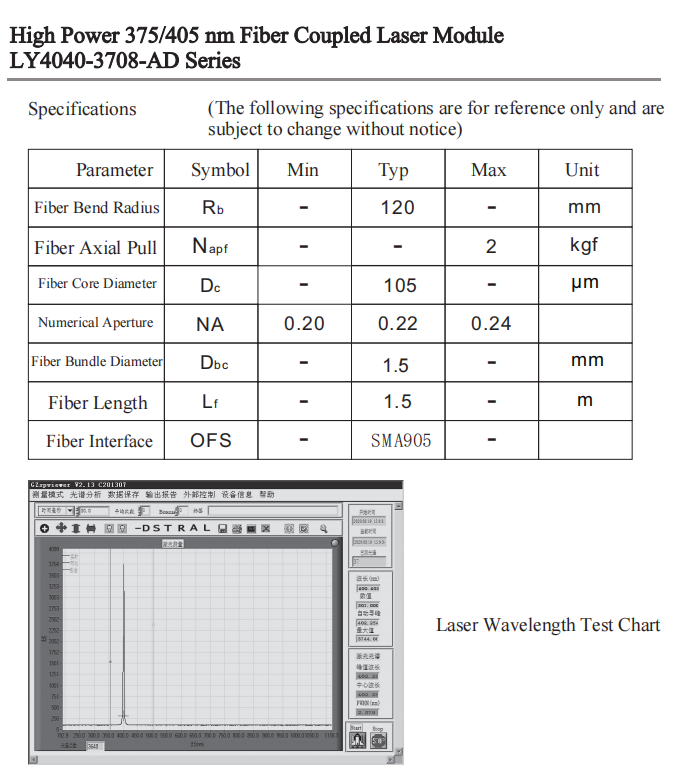

Dual-channel independent fiber coupling design: Each wavelength is coupled to UV-grade multimode silica fiber (core diameter customizable:105um/ 200μm/400μm, NA=0.22) with coupling efficiency ≥85% for both channels, minimizing optical loss and ensuring stable power transmission.

Shared fiber output option: Optional beam combiner integrates two wavelengths into a single fiber for coaxial dual-wavelength processing, ideal for hybrid tasks (e.g., 375nm patterning + 405nm curing in one step). Fiber length customizable (1m–20m) for flexible integration into lithography machines, laser processing stations, and automated production lines.

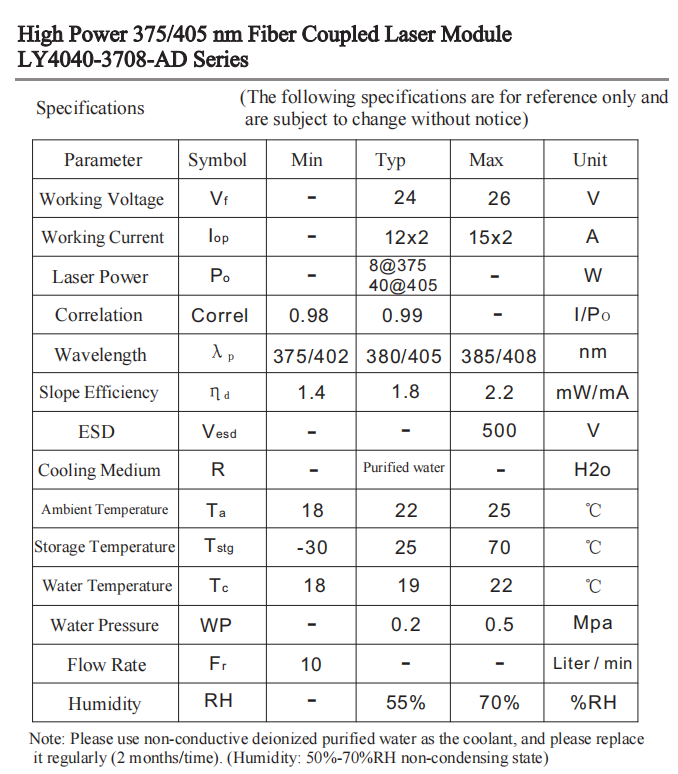

High-flow water cooling system: Maintains laser diode junction temperature ≤30°C for 405nm channel and ≤25°C for 375nm channel during full-power operation, ensuring MTBF ≥10,000 hours for industrial production lines.

Independent temperature & flow control for each channel: Prevents cross-interference between the two high-power laser diodes, ensuring wavelength stability and consistent beam quality.

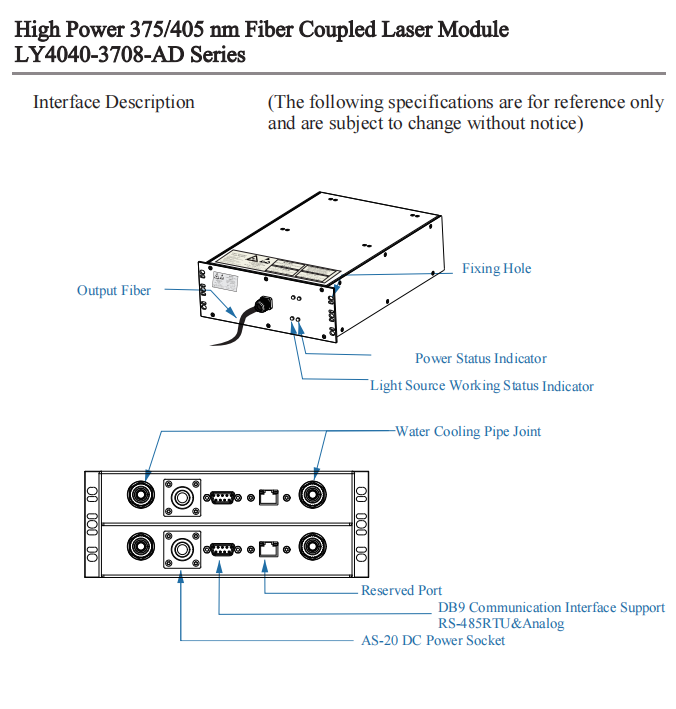

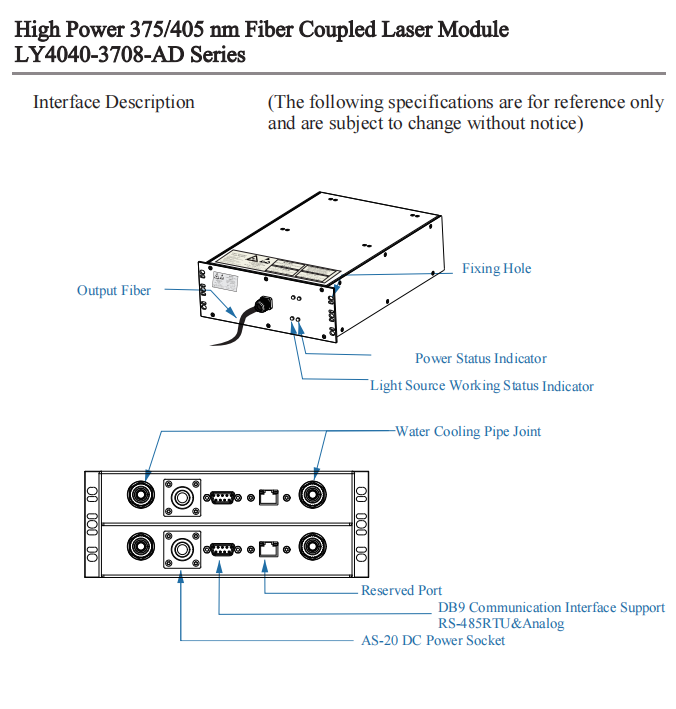

Leak-proof G1/4 water connectors compatible with mainstream industrial cooling loops; built-in flow rate monitoring and over-temperature protection trigger automatic shutdown for each channel independently, avoiding cascading damage to the module.

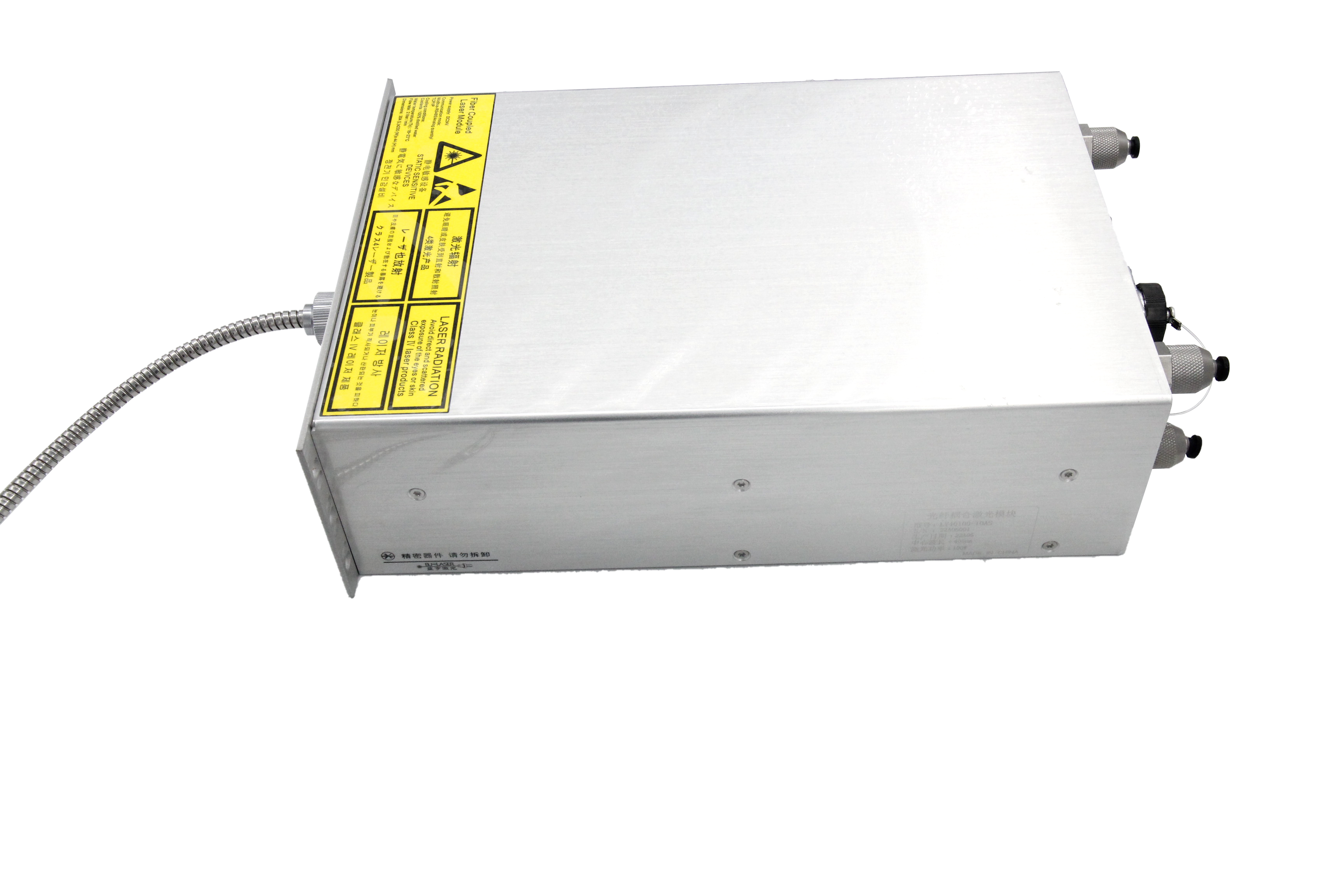

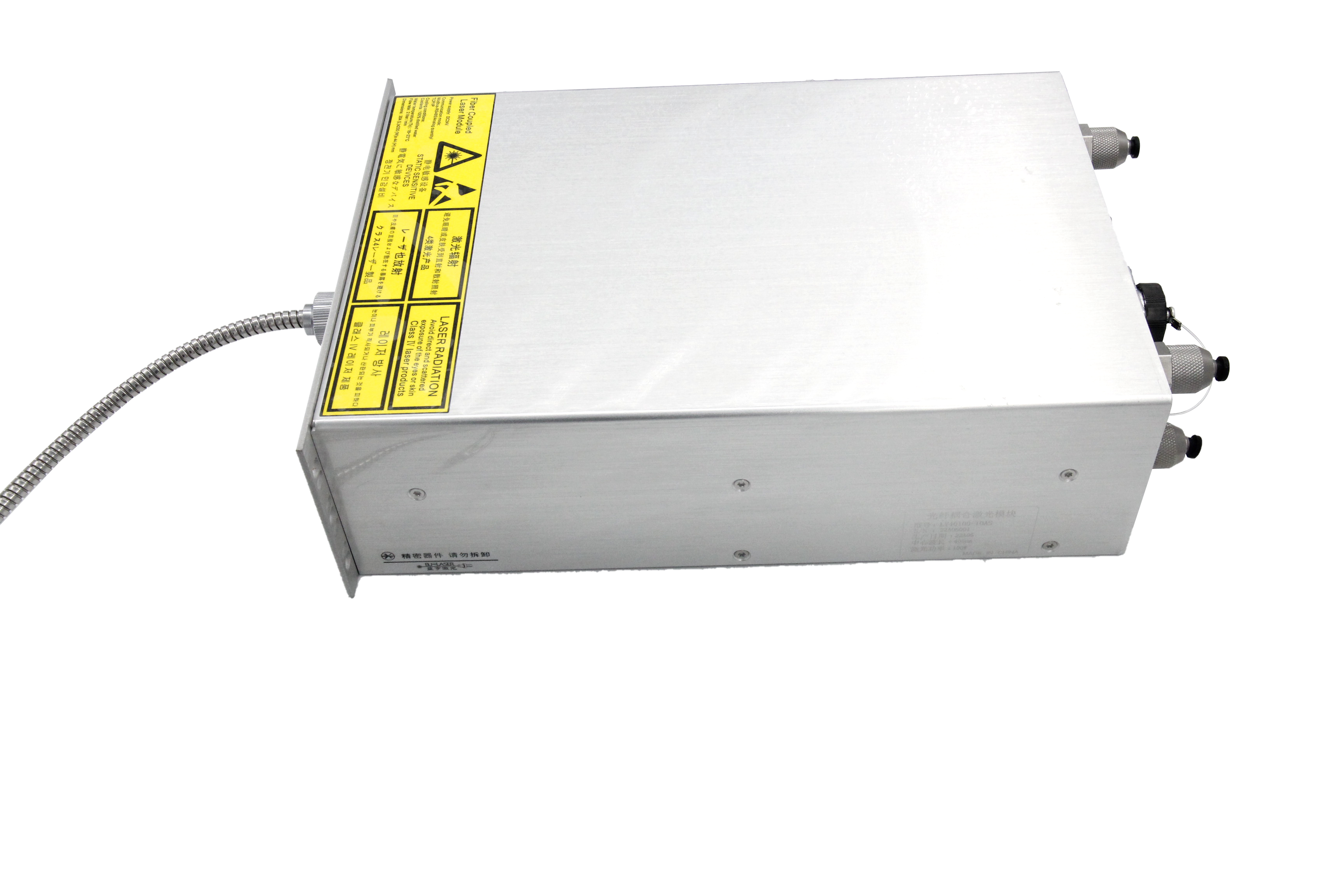

Sealed anodized aluminum alloy housing (IP54 dustproof) with UV-resistant coating, suitable for cleanroom and factory workshop environments—resists dust, moisture, and chemical fumes to protect internal optics.

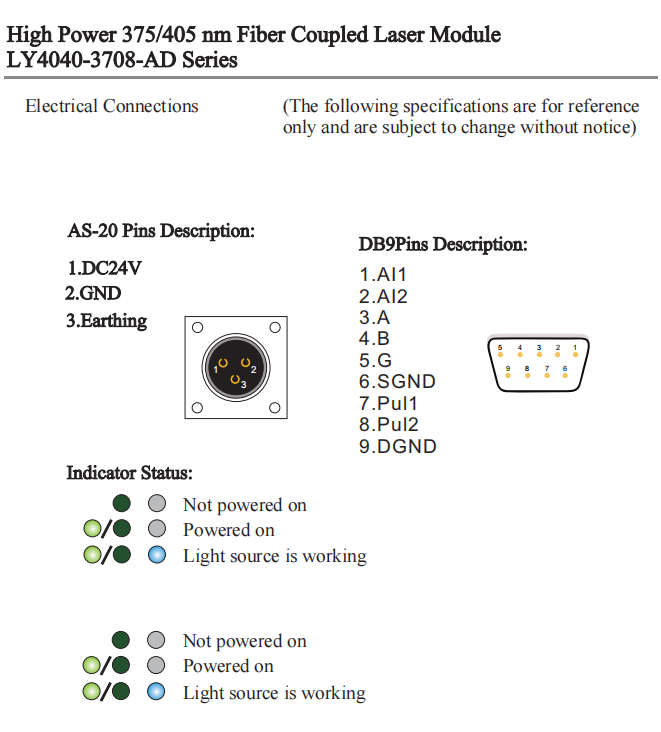

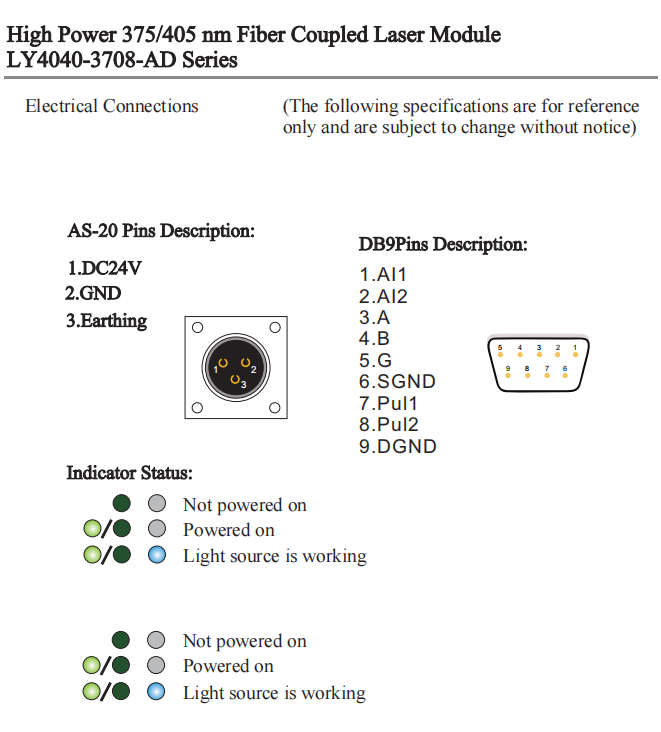

Multi-interface control system: RS485/Modbus communication interface supports remote monitoring and adjustment of power, modulation frequency, and temperature for each wavelength.

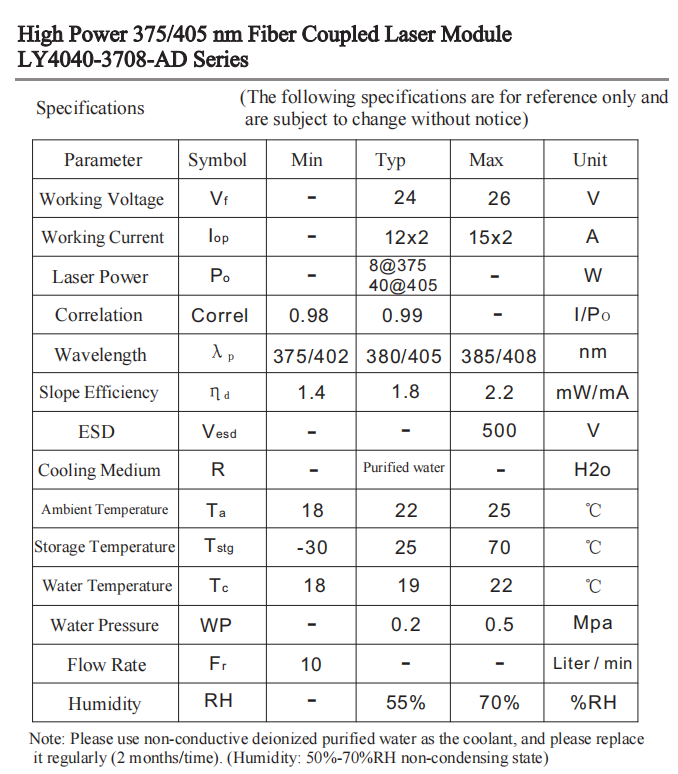

| Wavelength | 405nm/375nm |

| Output Power | 405nm-40W, 375nm-8W, then total 40W optical power |

| Working Voltage | 24V |

| Fiber Core Diameter | 105um , NA0.22, 1.5M length |

| Coupling Efficiency | 80%~85% |

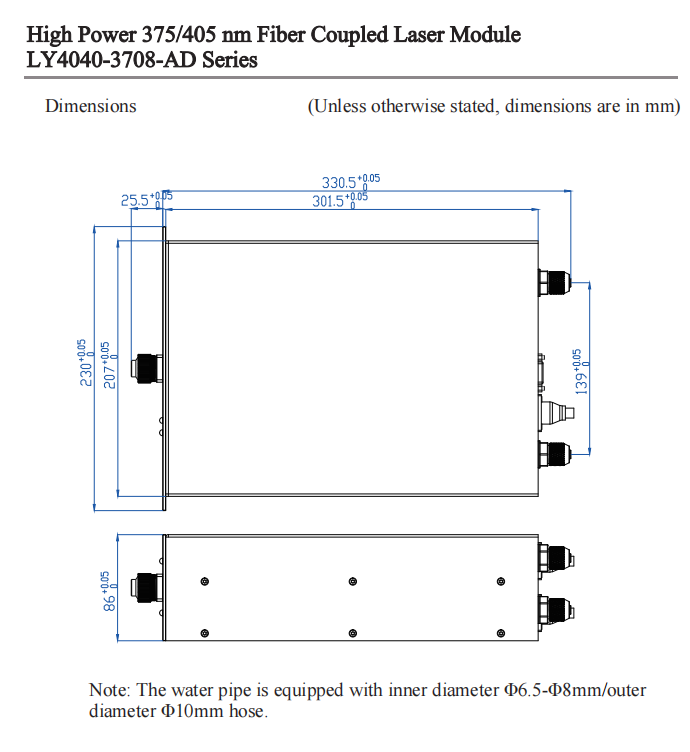

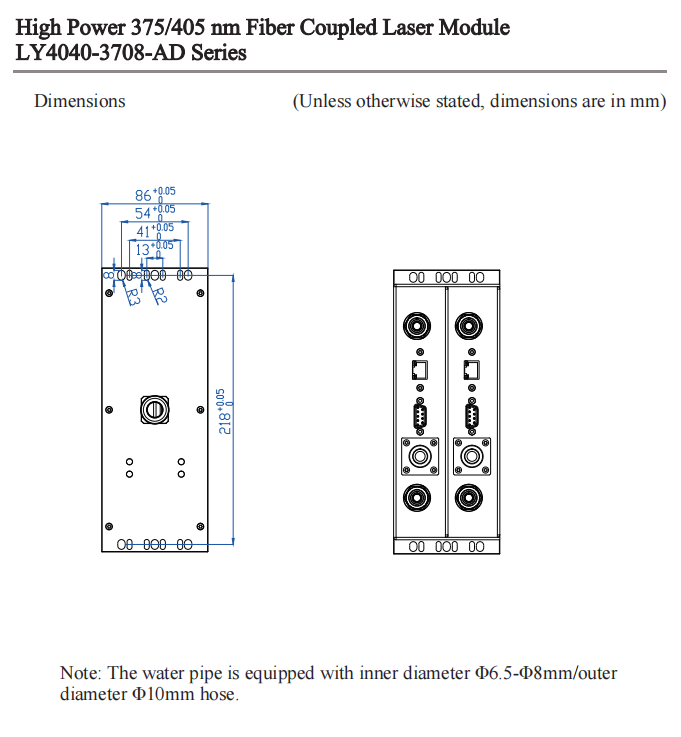

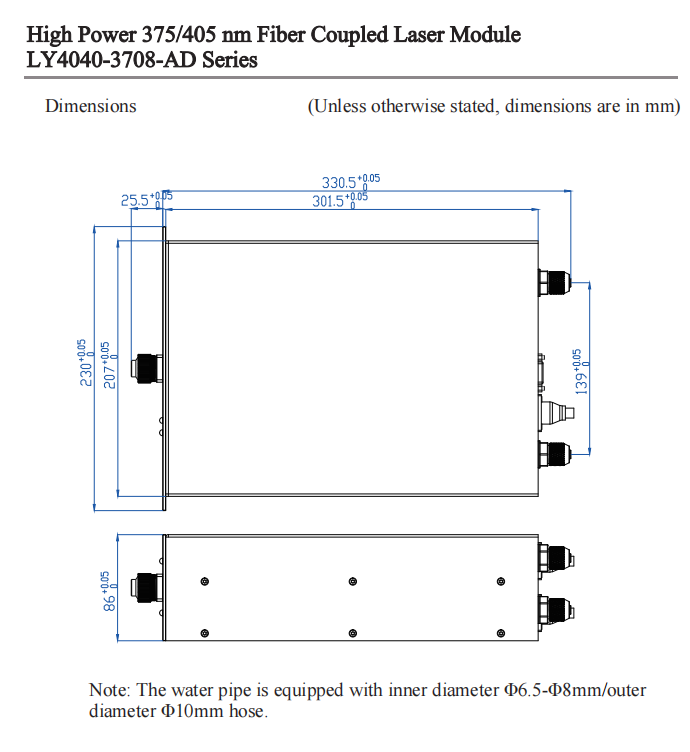

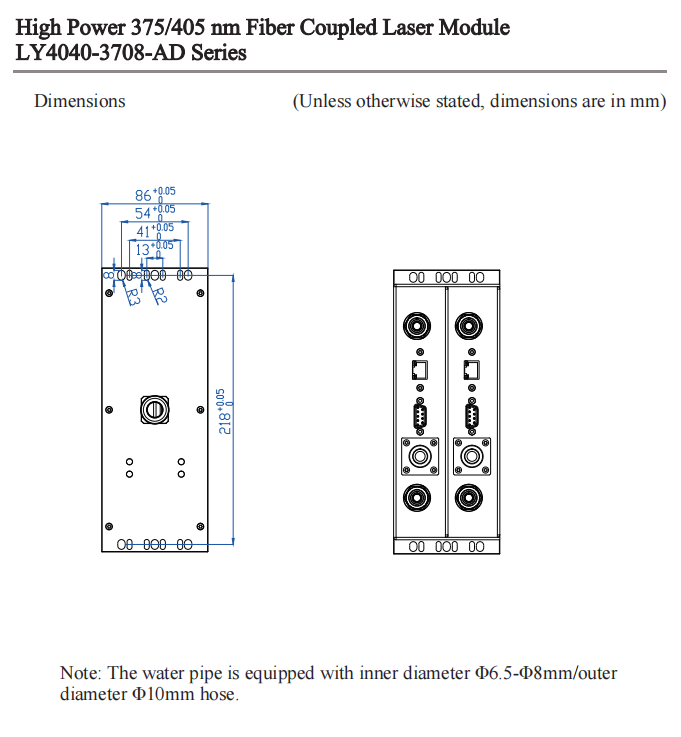

| Housing Size | 330*230*86mm (Customizable) |

| Lens | Optical Glass |

| Lifespan | > 10,000 hours |

Note: As it is a fiber-bundled laser, we can increase or decrease the quantity of the laser diode inside to change the power so that the power can be from 1W to 100W. And the fiber also can be selected by you!

We have over 15 years of experience with Lasers. We offer professional OEM& ODM service for laser modules!

| Item | Parameter | ||||

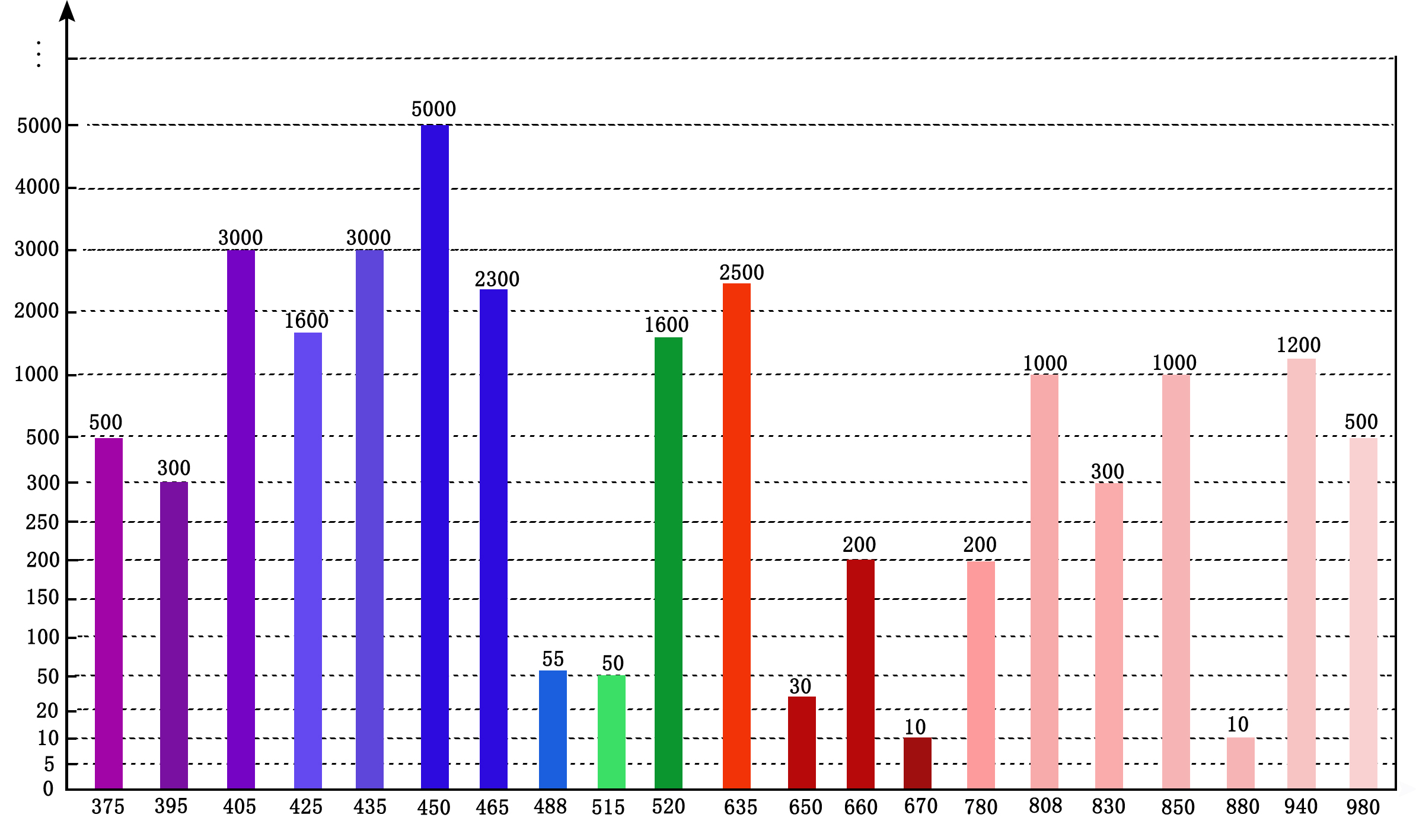

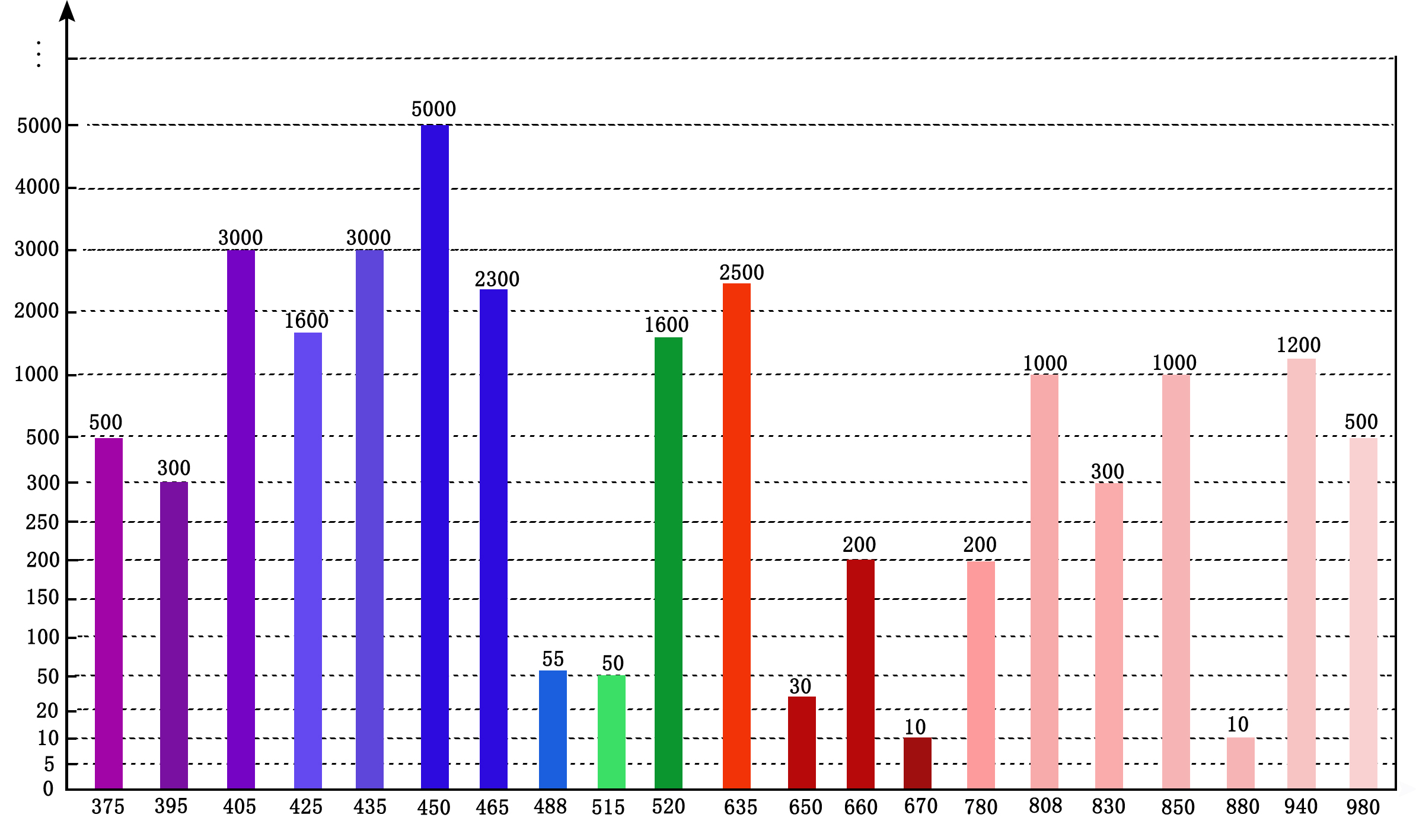

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/80°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||

The 2IN1 405nm 40W & 375nm 8W Dual Wavelength UV Fiber Coupled Laser Module—a high-power, multi-functional optical solution engineered for advanced microfabrication, semiconductor processing, PCB HDI (High-Density Interconnect) dual-process lithography, and UV-curable material manufacturing. Combining the high-efficiency processing capability of 405nm violet light and the ultra-high-resolution patterning advantage of 375nm near-UV light, this module delivers 48W total output power with independent wavelength control, enabling one-module integration of multiple precision processing workflows and reducing equipment investment costs.

375nm 8W Near-UV Wavelength: Targets high-resolution patterning scenarios—aligns with the absorption peak of g-line/h-line photoresists, enabling sub-1μm ultra-fine feature fabrication (e.g., semiconductor MEMS devices, microfluidic chip channels) with minimal heat-affected zones (HAZ ≤0.5μm). Ultra-narrow spectral linewidth (≤3nm FWHM) ensures consistent photoresist response, critical for critical dimension (CD) control in advanced manufacturing.

405nm 40W Violet Wavelength: Optimized for high-throughput processing—achieves 3–5x higher absorption efficiency on acrylate-based photoresists, UV-curable adhesives, and polymer composites than 375nm light, enabling single-pass fast exposure of 600mm×600mm PCB panels and rapid curing of thick conformal coatings. 40W high power cuts processing time by 70% compared to single-wavelength 10W modules.

Independent Wavelength Control: Both wavelengths support separate on/off switching and 0–100% PWM modulation, enabling flexible switching between high-resolution patterning (375nm) and high-speed processing (405nm) without reconfiguring the optical path.

Total 48W CW output power (40W+8W) delivers combined energy density ≥50,000mW/cm² at the fiber tip, supporting high-volume batch production of complex components that require both fine patterning and rapid processing.

Dual-channel independent fiber coupling design: Each wavelength is coupled to UV-grade multimode silica fiber (core diameter customizable:105um/ 200μm/400μm, NA=0.22) with coupling efficiency ≥85% for both channels, minimizing optical loss and ensuring stable power transmission.

Shared fiber output option: Optional beam combiner integrates two wavelengths into a single fiber for coaxial dual-wavelength processing, ideal for hybrid tasks (e.g., 375nm patterning + 405nm curing in one step). Fiber length customizable (1m–20m) for flexible integration into lithography machines, laser processing stations, and automated production lines.

High-flow water cooling system: Maintains laser diode junction temperature ≤30°C for 405nm channel and ≤25°C for 375nm channel during full-power operation, ensuring MTBF ≥10,000 hours for industrial production lines.

Independent temperature & flow control for each channel: Prevents cross-interference between the two high-power laser diodes, ensuring wavelength stability and consistent beam quality.

Leak-proof G1/4 water connectors compatible with mainstream industrial cooling loops; built-in flow rate monitoring and over-temperature protection trigger automatic shutdown for each channel independently, avoiding cascading damage to the module.

Sealed anodized aluminum alloy housing (IP54 dustproof) with UV-resistant coating, suitable for cleanroom and factory workshop environments—resists dust, moisture, and chemical fumes to protect internal optics.

Multi-interface control system: RS485/Modbus communication interface supports remote monitoring and adjustment of power, modulation frequency, and temperature for each wavelength.

| Wavelength | 405nm/375nm |

| Output Power | 405nm-40W, 375nm-8W, then total 40W optical power |

| Working Voltage | 24V |

| Fiber Core Diameter | 105um , NA0.22, 1.5M length |

| Coupling Efficiency | 80%~85% |

| Housing Size | 330*230*86mm (Customizable) |

| Lens | Optical Glass |

| Lifespan | > 10,000 hours |

Note: As it is a fiber-bundled laser, we can increase or decrease the quantity of the laser diode inside to change the power so that the power can be from 1W to 100W. And the fiber also can be selected by you!

We have over 15 years of experience with Lasers. We offer professional OEM& ODM service for laser modules!

| Item | Parameter | ||||

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/80°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||