| Availability: | |

|---|---|

| Quantity: | |

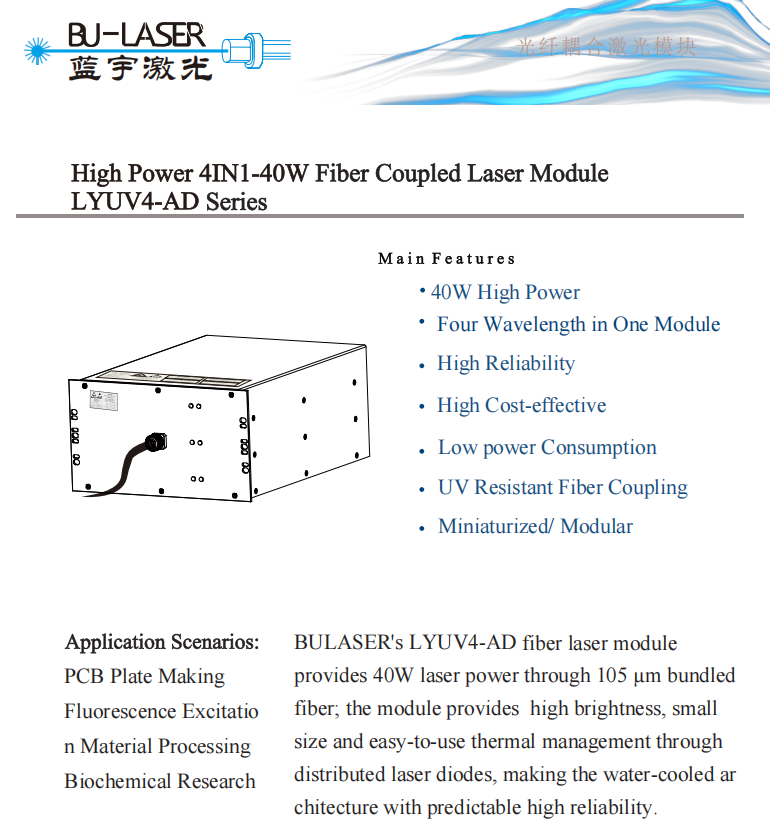

LYUV4-AD

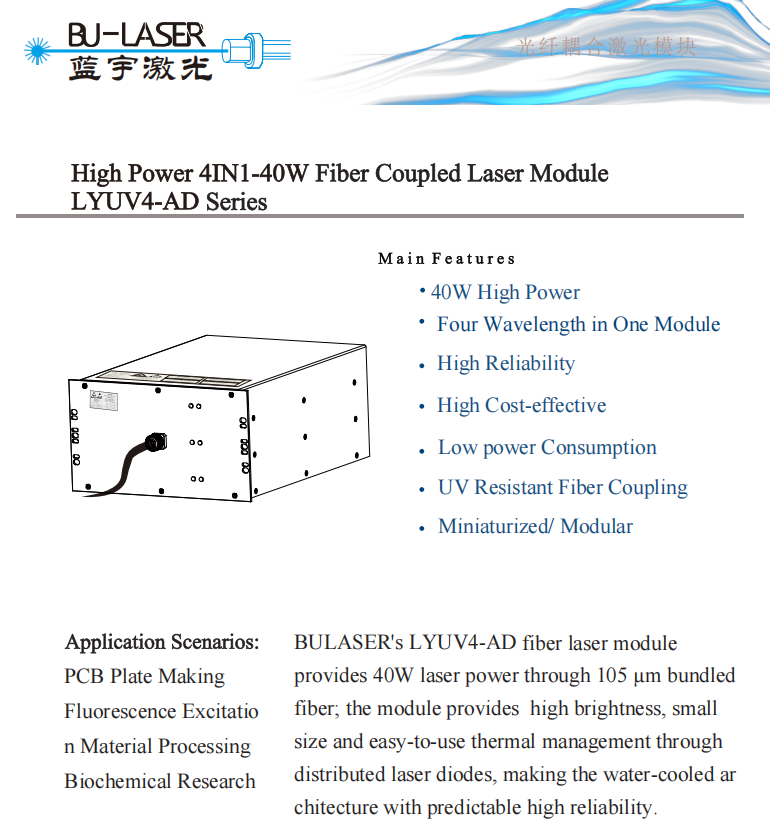

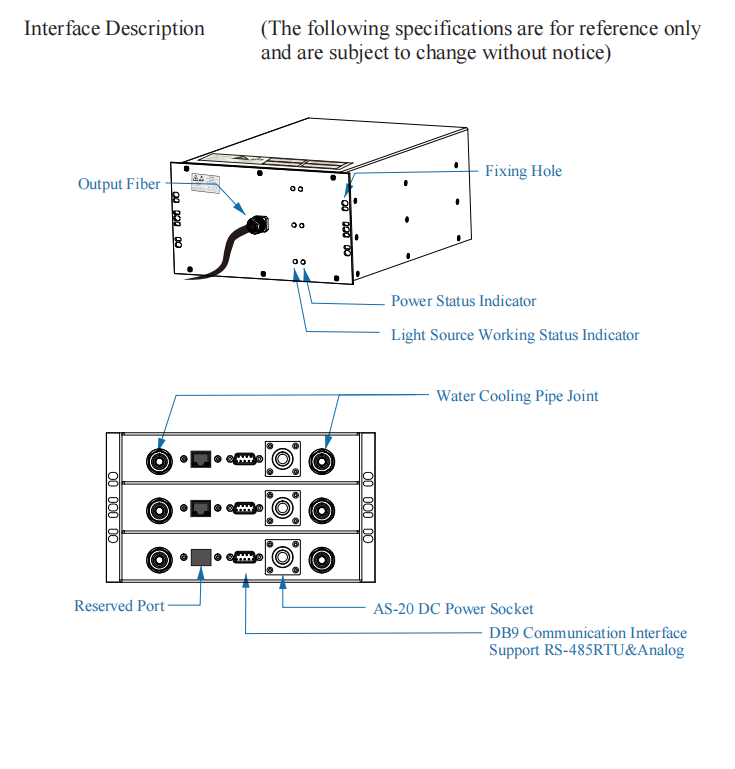

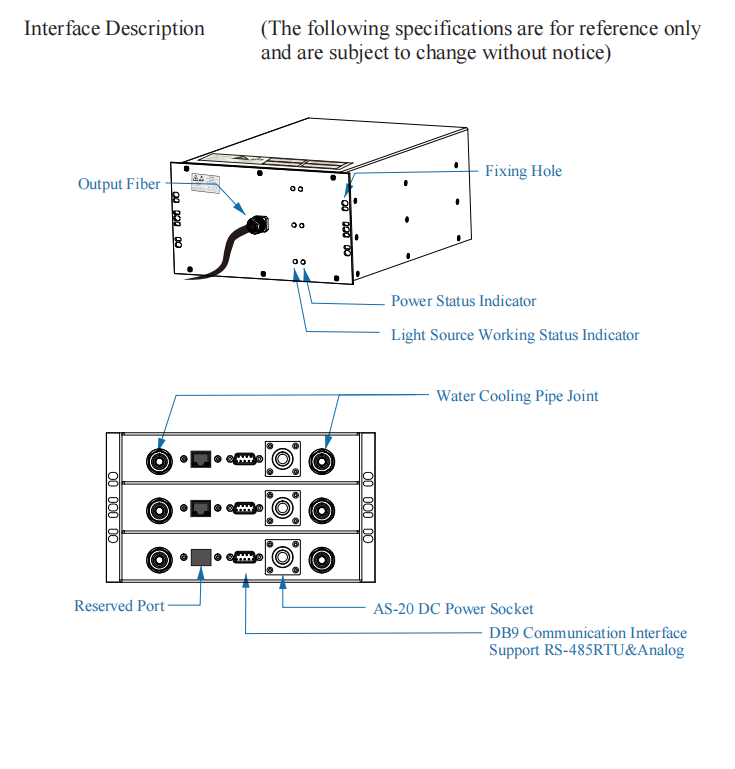

The 4IN1 40W Multi-Wavelength Fiber-Coupled Laser Module—a cutting-edge integrated solution engineered exclusively for PCB mask curing (solder mask, photoresist curing) in high-volume electronics manufacturing. Combining four UV-violet wavelengths (375nm/405nm/415nm/435nm) with 40W total output power and precision fiber coupling, this module delivers tailored energy absorption for diverse PCB mask resins, ensuring ultra-fast curing, uniform film quality, and compatibility with rigid PCBs, FPCs, and HDI boards.

1. 4-In-1 Multi-Wavelength Optimization: Universal Resin Compatibility

375nm UV-A: Aligns with absorption peaks of epoxy-based solder masks, enabling deep curing of thick masks (≥50μm) without thermal deformation.

405nm Violet: Optimized for acrylate-based photoresists and HDI board fine-patterning (sub-10μm linewidths), ensuring sharp edge definition.

415nm Violet-Blue: Enhances curing efficiency of hybrid resins (epoxy-acrylate blends), reducing oxygen inhibition for smoother mask surfaces.

435nm Blue-Violet: Improves adhesion of low-viscosity solder masks on copper traces, minimizing pinholes and micro-cracks.

Independent Power Control: Each wavelength supports 5W–15W adjustable output (total 40W), allowing customization for specific resin formulations and PCB thicknesses.

2. 40W High Total Power: Boost Production Throughput

With water cooling systems built in, Stable CW output with ≤±2% power fluctuation per wavelength.

Reduces curing time by 70% compared to single-wavelength 10W modules (e.g., 1.2mm thick PCB mask cured in ≤2 seconds vs. 6+ seconds).

Supports high-speed inline production (up to 3m/min conveyor speed) for mass PCB manufacturing, without compromising curing uniformity.

3. Precision Fiber-Coupled Delivery: Uniform Curing Across PCB Surfaces

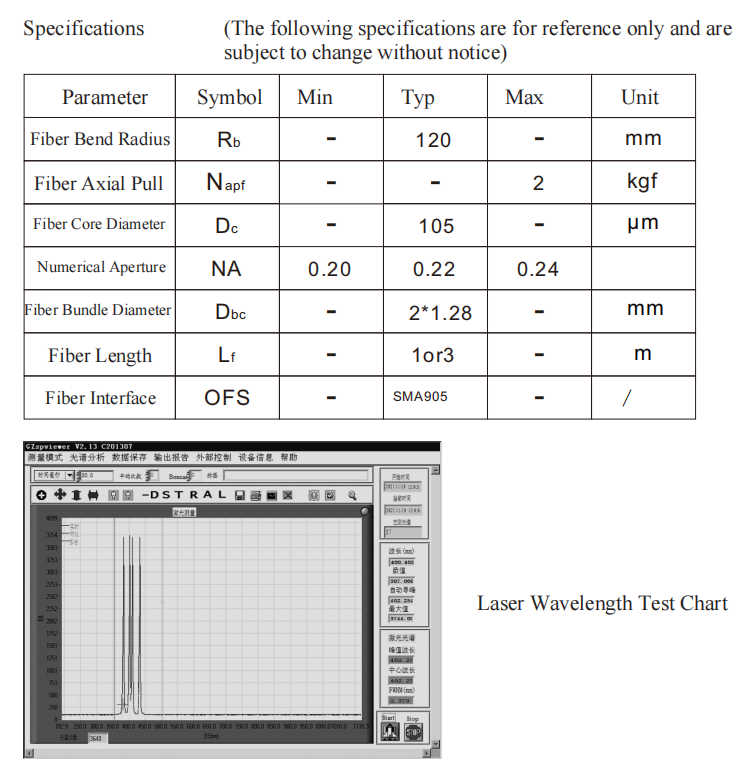

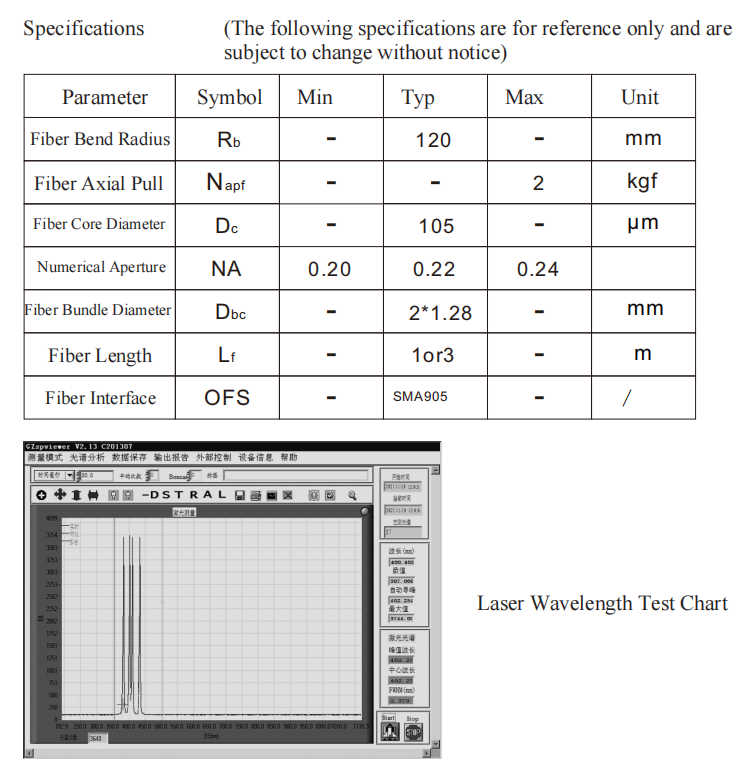

Equipped with UV-grade multimode silica fiber (core diameter 105, NA=0.22, total coupling efficiency ≥95%).

Single-fiber coaxial output of all four wavelengths ensures uniform energy distribution across large PCB areas (up to 600mm×600mm) and complex geometries (e.g., blind vias, microvias).

Fiber length customizable (1.5m–5m) with SMA-905/ FC industrial connector, adapting to inline curing stations, robotic arms, or automated PCB lines.

Primary Application: Solder mask curing for rigid PCBs, flexible FPCs, HDI boards, IC substrates, and automotive electronics PCBs.

Resin Compatibility: Epoxy-based, acrylate-based, and hybrid (epoxy-acrylate) solder masks; liquid photoresists (LFR) and dry film photoresists (DFR).

Extended Applications: Conformal coating curing for PCB assemblies, microfluidic chip photoresist curing, and high-precision electronic component patterning.

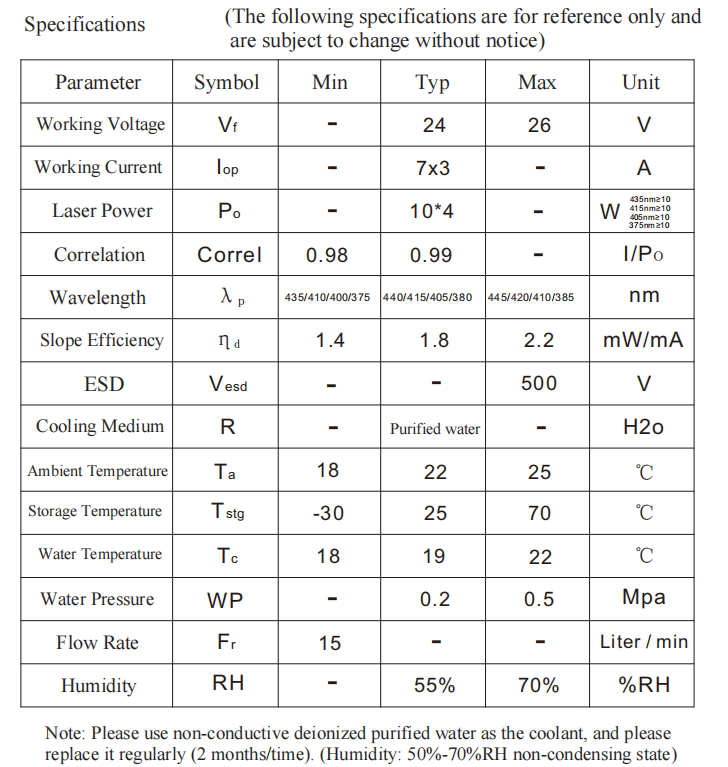

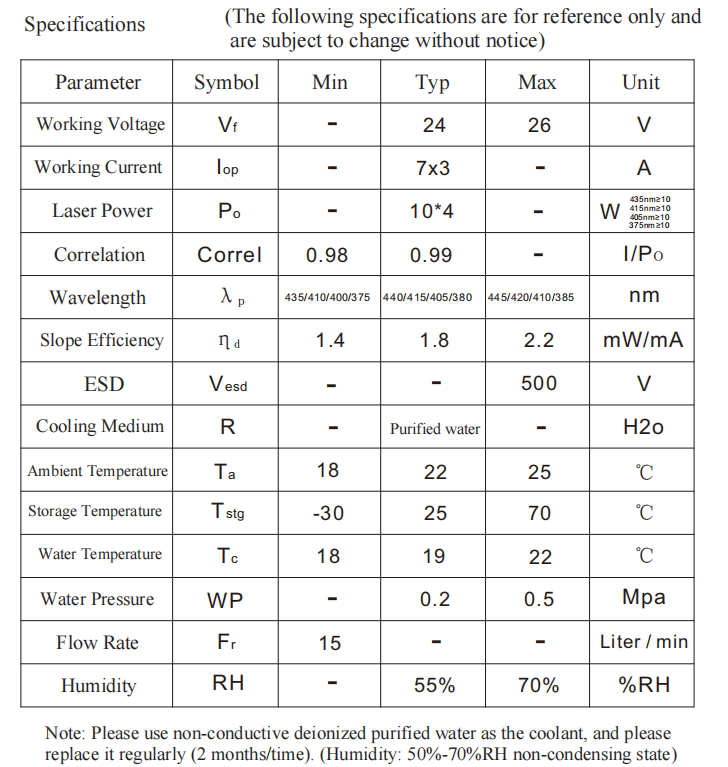

Core Specification :

| Wavelength | 405nm/ 415nm/435nm/375nm |

| Output Power | 10W of each wavelength, then total 40W optical power |

| Working Voltage | 24V |

| Fiber Core Diameter | 105um , NA0.22, 3M length |

| Coupling Efficiency | 80%~85% |

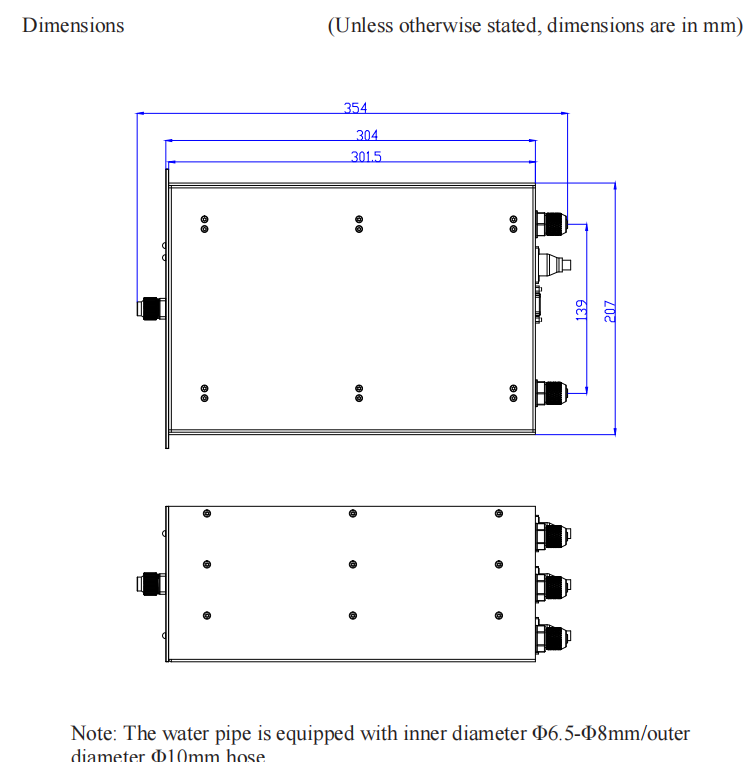

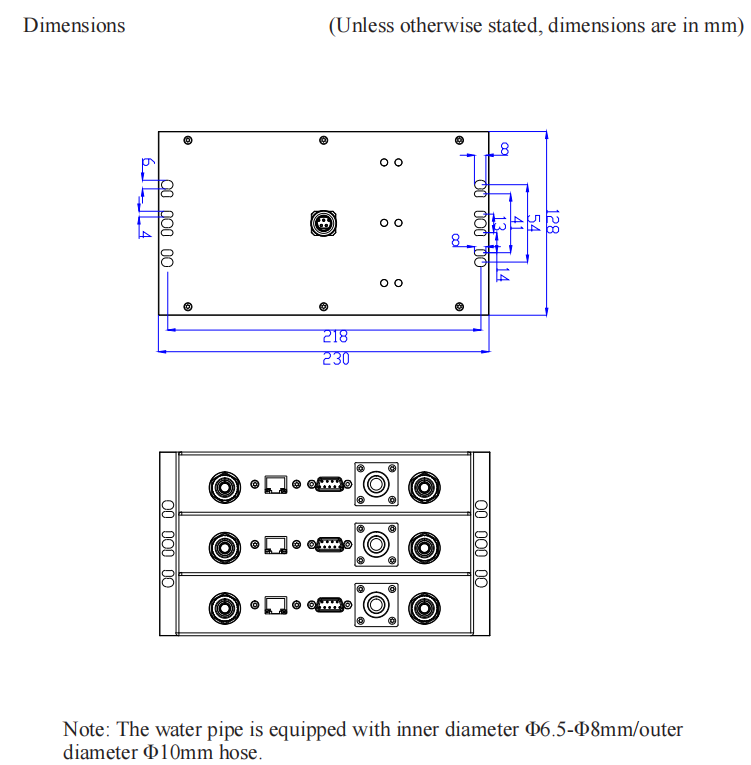

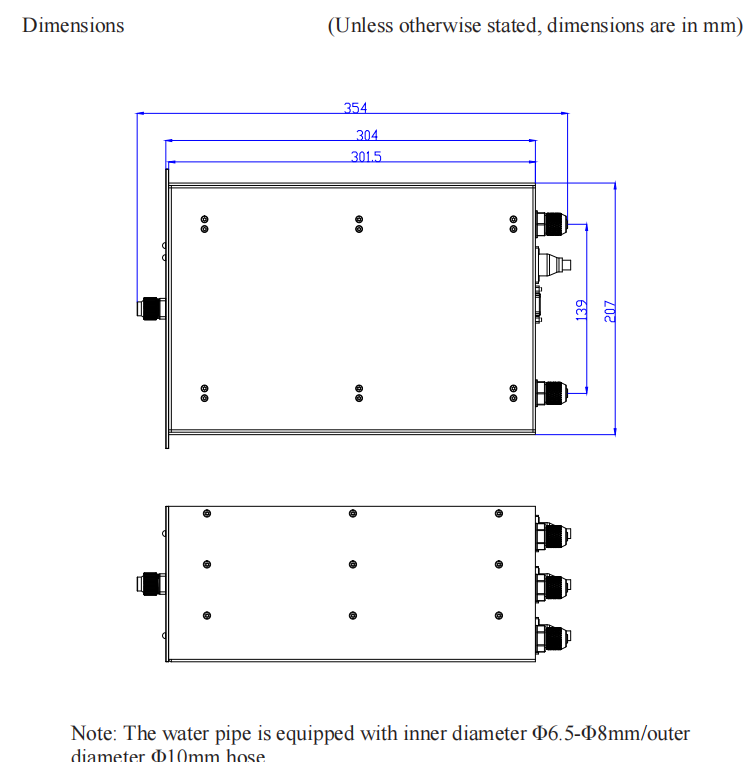

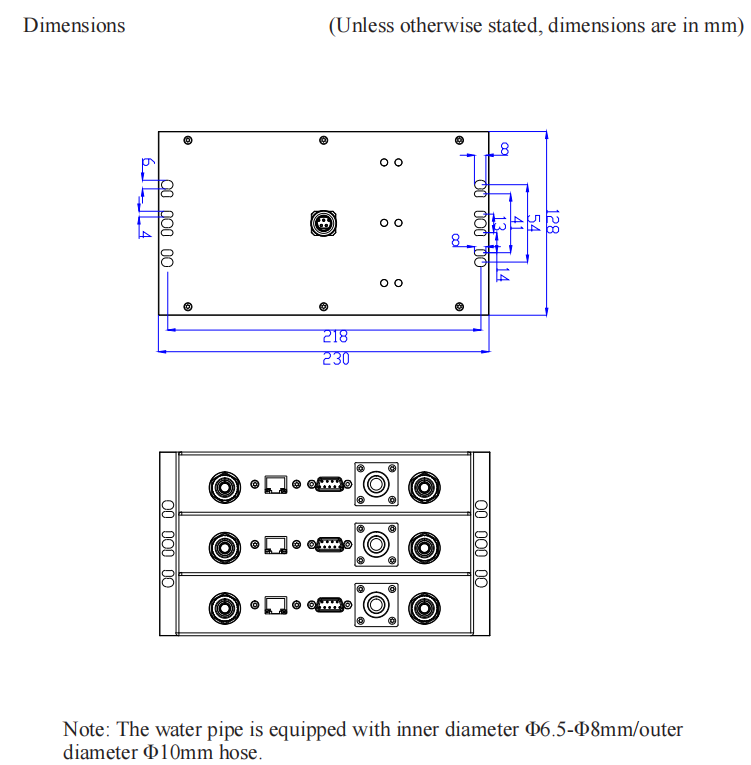

| Housing Size | 354*207*128mm (Customizable) |

| Lens | Optical Glass |

| Lifespan | > 10,000 hours |

Note: As it is a fiber-bundled laser, we can increase or decrease the quantity of the laser diode inside to change the power so that the power can be from 1W to 100W. And the fiber also can be selected by you!

| Item | Parameter | ||||

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

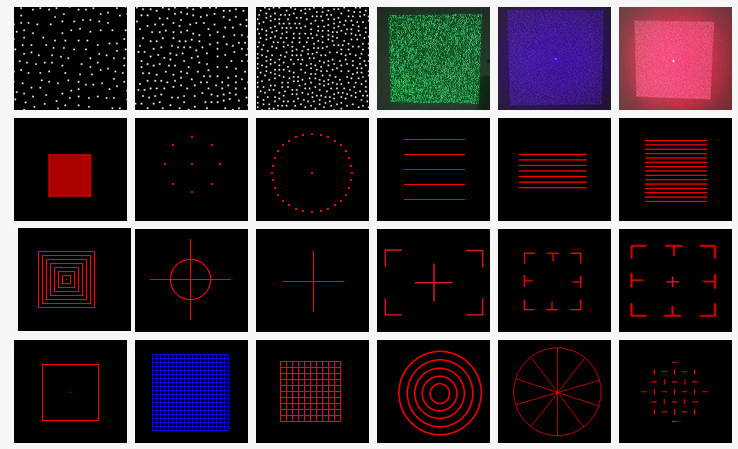

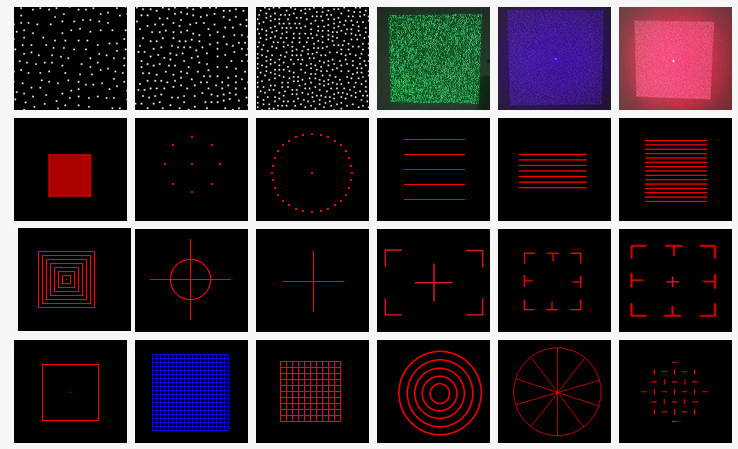

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/90°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||

The Below are other laser pattern options you can select:

The 4IN1 40W Multi-Wavelength Fiber-Coupled Laser Module—a cutting-edge integrated solution engineered exclusively for PCB mask curing (solder mask, photoresist curing) in high-volume electronics manufacturing. Combining four UV-violet wavelengths (375nm/405nm/415nm/435nm) with 40W total output power and precision fiber coupling, this module delivers tailored energy absorption for diverse PCB mask resins, ensuring ultra-fast curing, uniform film quality, and compatibility with rigid PCBs, FPCs, and HDI boards.

1. 4-In-1 Multi-Wavelength Optimization: Universal Resin Compatibility

375nm UV-A: Aligns with absorption peaks of epoxy-based solder masks, enabling deep curing of thick masks (≥50μm) without thermal deformation.

405nm Violet: Optimized for acrylate-based photoresists and HDI board fine-patterning (sub-10μm linewidths), ensuring sharp edge definition.

415nm Violet-Blue: Enhances curing efficiency of hybrid resins (epoxy-acrylate blends), reducing oxygen inhibition for smoother mask surfaces.

435nm Blue-Violet: Improves adhesion of low-viscosity solder masks on copper traces, minimizing pinholes and micro-cracks.

Independent Power Control: Each wavelength supports 5W–15W adjustable output (total 40W), allowing customization for specific resin formulations and PCB thicknesses.

2. 40W High Total Power: Boost Production Throughput

With water cooling systems built in, Stable CW output with ≤±2% power fluctuation per wavelength.

Reduces curing time by 70% compared to single-wavelength 10W modules (e.g., 1.2mm thick PCB mask cured in ≤2 seconds vs. 6+ seconds).

Supports high-speed inline production (up to 3m/min conveyor speed) for mass PCB manufacturing, without compromising curing uniformity.

3. Precision Fiber-Coupled Delivery: Uniform Curing Across PCB Surfaces

Equipped with UV-grade multimode silica fiber (core diameter 105, NA=0.22, total coupling efficiency ≥95%).

Single-fiber coaxial output of all four wavelengths ensures uniform energy distribution across large PCB areas (up to 600mm×600mm) and complex geometries (e.g., blind vias, microvias).

Fiber length customizable (1.5m–5m) with SMA-905/ FC industrial connector, adapting to inline curing stations, robotic arms, or automated PCB lines.

Primary Application: Solder mask curing for rigid PCBs, flexible FPCs, HDI boards, IC substrates, and automotive electronics PCBs.

Resin Compatibility: Epoxy-based, acrylate-based, and hybrid (epoxy-acrylate) solder masks; liquid photoresists (LFR) and dry film photoresists (DFR).

Extended Applications: Conformal coating curing for PCB assemblies, microfluidic chip photoresist curing, and high-precision electronic component patterning.

Core Specification :

| Wavelength | 405nm/ 415nm/435nm/375nm |

| Output Power | 10W of each wavelength, then total 40W optical power |

| Working Voltage | 24V |

| Fiber Core Diameter | 105um , NA0.22, 3M length |

| Coupling Efficiency | 80%~85% |

| Housing Size | 354*207*128mm (Customizable) |

| Lens | Optical Glass |

| Lifespan | > 10,000 hours |

Note: As it is a fiber-bundled laser, we can increase or decrease the quantity of the laser diode inside to change the power so that the power can be from 1W to 100W. And the fiber also can be selected by you!

| Item | Parameter | ||||

| Wavelength | 375-405nm | 425-488nm | 515-520nm | 635-670nm | 780-980nm |

| Single Diode Module Optical Power | 20mW-3W | 20mW-3W | 10mW-1.6W | 5mW-2.5W | 5mW-75W |

| Multi Diodes Module Optical Power | 3W-200W | 6W-500W | 1.6W-50W | 2.5W-30W | 75W-100W |

| Operating Voltage | 3-5V/6V/ 12V/ 24V/ 30V/ 110V/ 220V/ 240V etc. | ||||

| Spot Mode | Dot/ Line/ Cross/ Grid/ Muti-lines/ DOE etc. | ||||

| Fan Angle Options of the Line Beam | 5°/10°/15°/20°/25°/30°/45°/60°/90°/110°/130°/180° etc. | ||||

| Optical Lens | Acrylic lenses, glass lenses, wave lenses, Powell lenses etc. | ||||

| Dimension | 4*8mm/ 6*10.5mm/12*15mm/9*21mm/16*66mm/ 33*33*55mm etc. | ||||

| CDRH Class | class1/class2/class3R/class3B/class4 | ||||

The Below are other laser pattern options you can select: